About Production Intelligence

Revolutionize Operations with Real-time Insights and Optimization

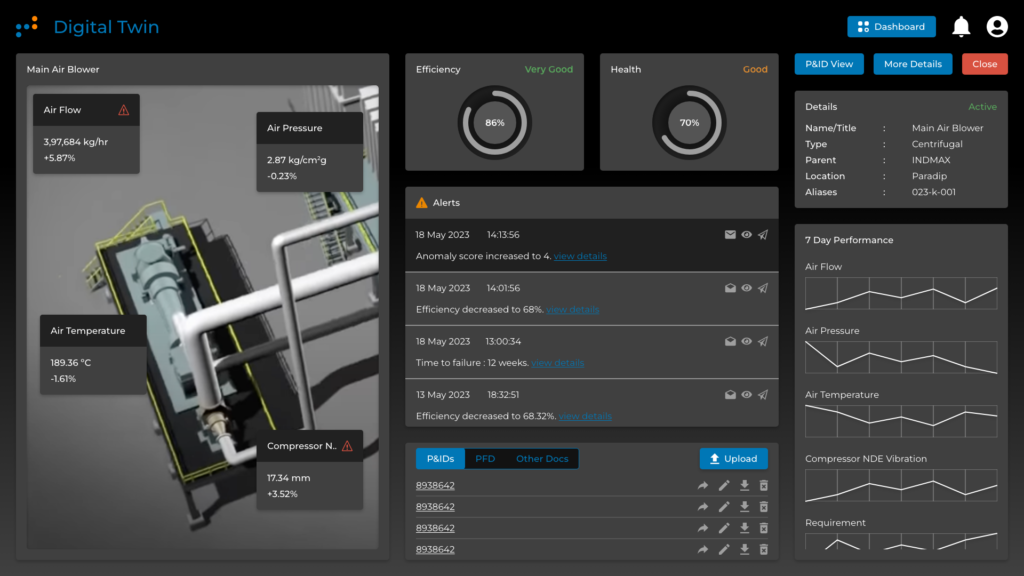

- Digital Twin Integration: Create a virtual replica of your plant for accurate real-time monitoring and decision-making.

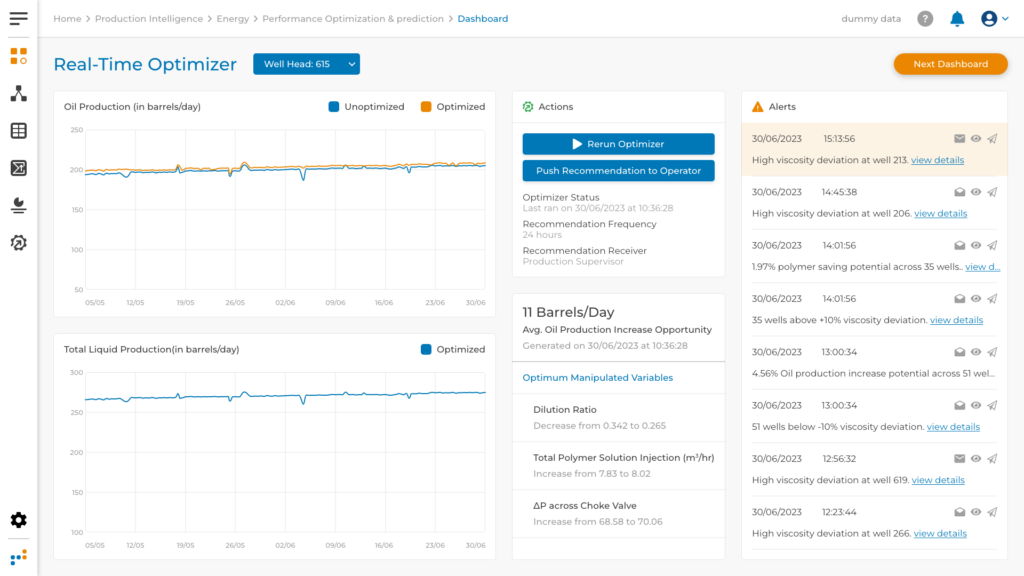

- Production & Schedule Optimization: Employ predictive algorithms to optimize production schedules, enhance resource utilization, and minimize downtime.

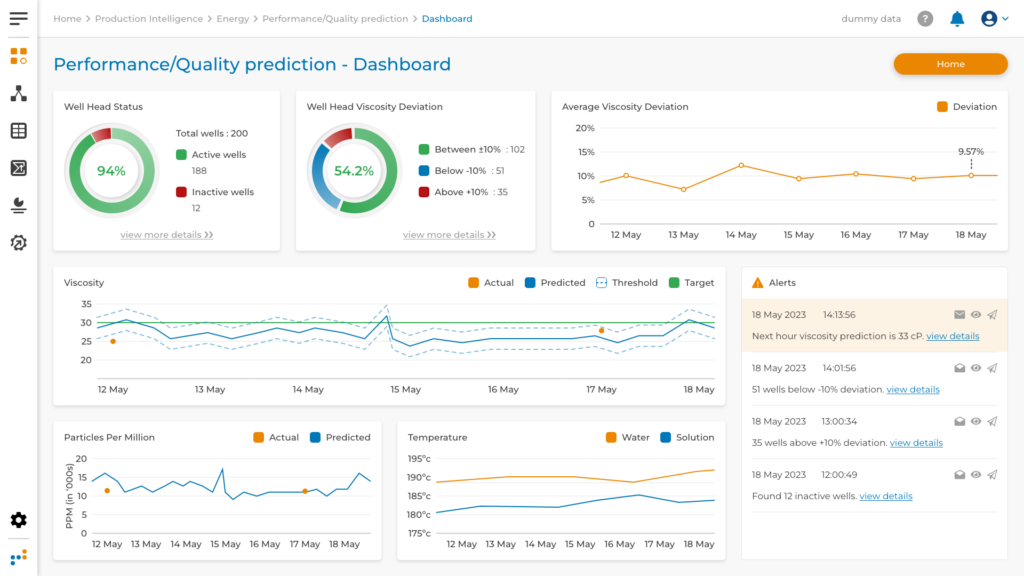

- Performance & Quality Prediction: Utilize data analytics to foresee performance issues and quality deviations, enabling proactive maintenance.

What we can help you achieve

Increase in Yield

Improvement in Throughput

Improved Product Quality

Increase in Operational Efficiency

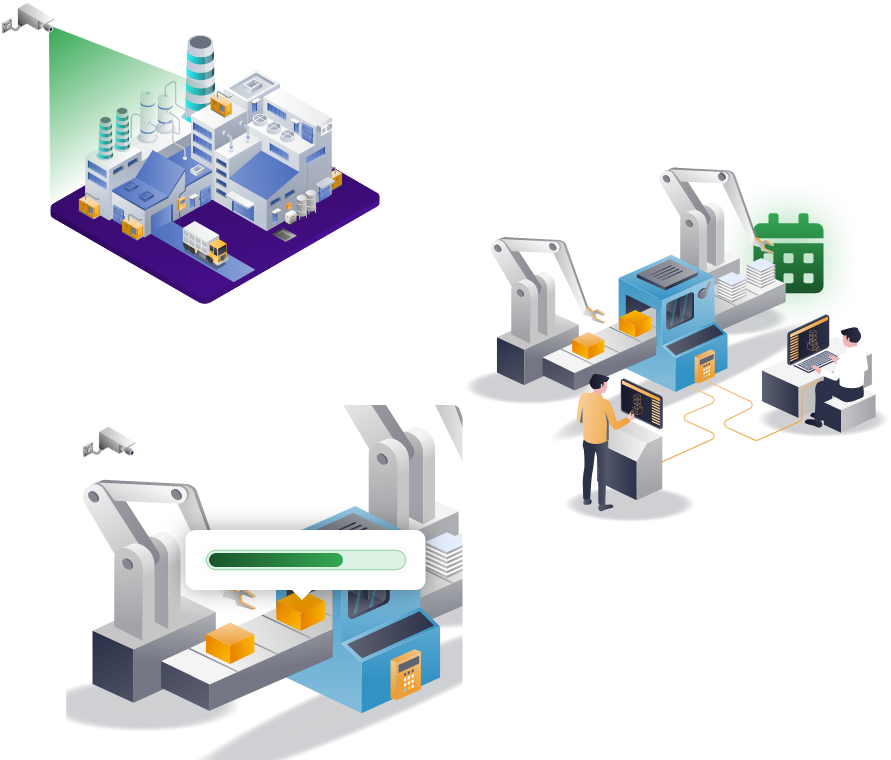

Sub Modules

Experience the power of real-time insights and proactive decision-making with our digital twin solution, transforming asset monitoring and maintenance for optimal performance and efficiency.

Streamline production scheduling with our solution, enabling efficient resource allocation, real-time monitoring, and inventory management for improved operational productivity and on-time delivery.

Streamline production scheduling with our solution, enabling efficient resource allocation, real-time monitoring, and inventory management for improved operational productivity and on-time delivery.

Optimize quality control and assurance with our advanced solution, ensuring proactive identification and resolution of quality issues for enhanced product reliability and customer satisfaction.

Applicable Industries

Hear it from Our Clients

Hindalco

The Algo8 team implemented a successful digital solution that transformed our perception of Coal Procurement at Aditya Aluminium. Their time-series models for real-time parameters like GCV improved the precision and efficiency of our Coal Chain. In 4 months, Algo8 team gave us a competitive edge, enhancing our systems and processes.

HMEL

Algo8 is working to deploy its process module to create better foresight for Operators on quality parameters for tighter control and optimised grade change over.

Kanpur Plastipack Ltd.

Really fascinated by the possibility after experiencing a first-hand solution to hard to measure problems. Super excited to onboard more AI modules from Algo8

IOCL

The technology has brought about a 360-degree turnaround that has solved the critical setbacks such as leakages, pressures, temperature, vibrations and unplanned breakdowns. We have observed op-ex cuts by reducing the failure quotient of the equipment.

A Fortune 500 Co.

General ManagerThe technology has brought about a 360-degree turnaround that has solved critical setbacks causing unplanned breakdowns. We have observed op-ex cuts by reducing the failure quotient of the equipment

A Leading Upstream O&G Co.

Business Advisor"An excellent team and an even better product. We have straight away saved $1mn in the past 6 months alone."

IOCL

COO“We have been working with Algo8 for the past 2 years. We started with 1 refinery but now have rolled out their products to 8 refineries. It has been a pleasure working with them”