Smart Production Scheduling to Minimize Planning Losses and Material Losses

Problem

The production scheduling process is critical for optimizing resources, minimizing planning losses, and reducing material losses in manufacturing operations. However, traditional production scheduling methods may lack real-time visibility and flexibility, leading to inefficiencies, missed opportunities for optimization, and increased material wastage. The challenges faced include:

- Lack of Real-time Visibility: The absence of a planning dashboard for site-schedulers hinders their ability to visualize and adjust production plans in response to ad-hoc changes on a day-to-day basis.

- Limited Performance Insights: Without equipment-wise production planning, performance, and utilization reports on a dashboard, it becomes challenging to track and optimize resource allocation efficiently.

- Inefficient Production Scheduling: Relying on manual processes or limited data from SAP ERP might result in suboptimal production scheduling, leading to planning losses and material wastage.

- Handling Change Requests: The difficulty in adopting change requests from the demand and production teams can lead to production inefficiencies and increased losses.

- Ineffective Issue Management: The inability to capture daily issues and non-adherence to the production plan can hinder process improvement and problem-solving efforts.

- User Management and Access Control: A lack of user management at the plant level, with roles and access controls, may pose security and data integrity risks.

Approach

To address the challenges and improve production scheduling, the company adopts a Smart Production Scheduling approach, leveraging the following strategies:

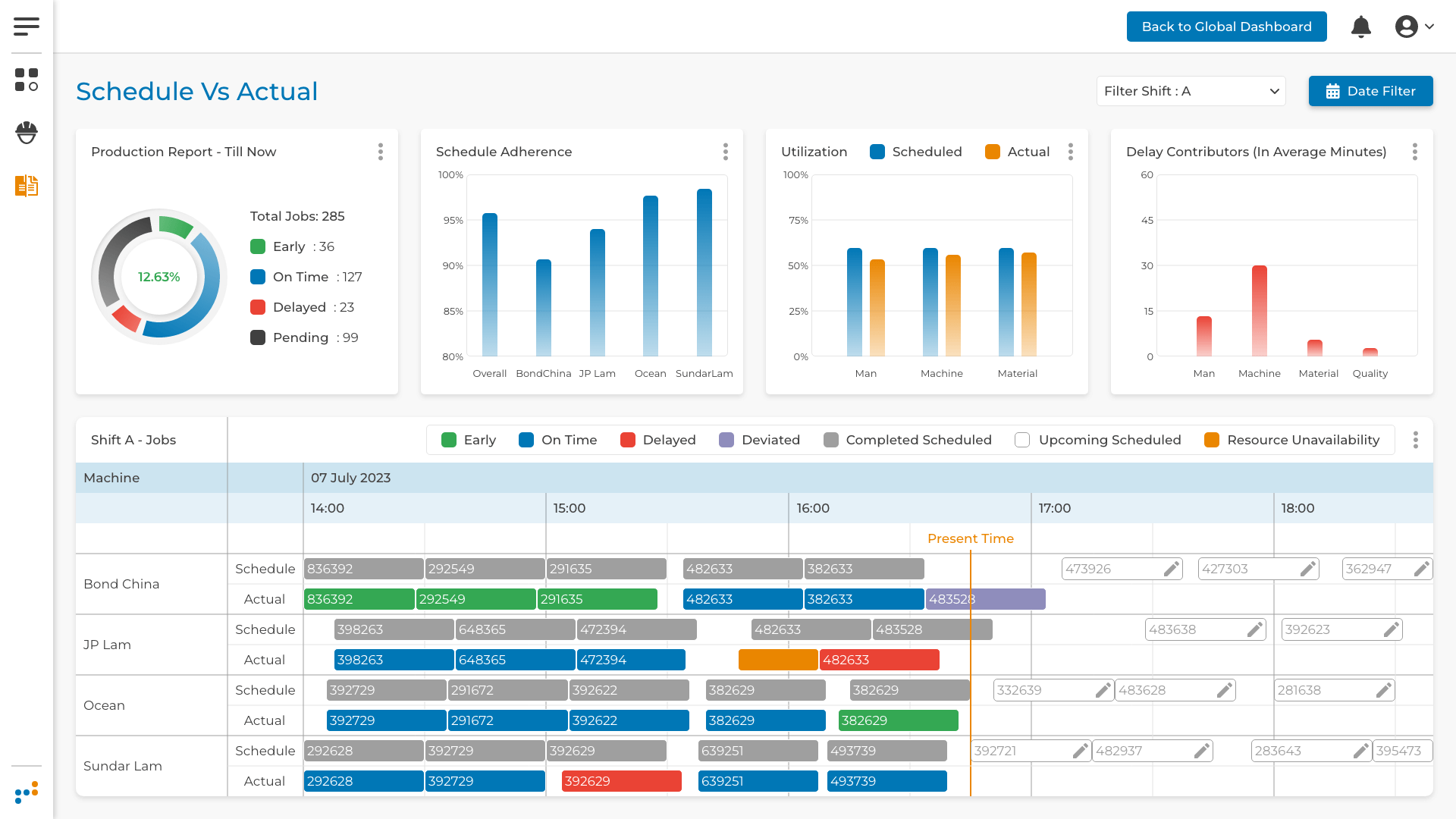

- Planning Dashboard: Implementing a planning dashboard empowers site-schedulers to visualize the production plan and make real-time adjustments based on ad-hoc changes and unexpected events.

- Equipment-Wise Reporting: By integrating equipment-wise production planning, performance, and utilization reports into the dashboard, the company gains deeper insights into resource allocation and equipment performance, enabling more informed decision-making.

- Smart Scheduling with SAP ERP Data: Utilizing various parameters from SAP ERP, such as production demand, resource availability, and material availability, enables smarter and more data-driven production scheduling decisions.

- Change Request Adoption: The Smart Production Scheduling system incorporates a mechanism to efficiently adopt change requests from the demand and production teams, ensuring seamless and adaptive scheduling.

- Issue Tracking and Reporting: The system captures daily issues and deviations from the production plan, facilitating root cause analysis and process improvement efforts.

- User Management and Access Control: The Smart Production Scheduling system includes user management capabilities at the plant level, with role-based access controls to ensure data security and integrity.

Benefit

The adoption of Smart Production Scheduling brings several benefits to the manufacturing operation:

- Real-time Planning: Site-schedulers can make informed decisions and adapt the production plan in real-time, reducing planning losses and optimizing resource utilization.

- Enhanced Visibility: Equipment-wise production reports provide better insights into performance, leading to optimized resource allocation and reduced material losses.

- Data-Driven Scheduling: Utilizing SAP ERP data and smart algorithms leads to more data-driven and optimized production scheduling decisions.

- Responsive Change Management: Efficient adoption of change requests improves production efficiency and minimizes disruptions caused by unexpected changes.

- Issue Resolution and Process Improvement: Daily issue tracking helps identify bottlenecks and inefficiencies, leading to continuous process improvement.

- Data Security and Control: User management with role-based access control ensures data security and restricts unauthorized access to sensitive information.

By adopting Smart Production Scheduling, the company achieves improved production efficiency, minimized losses, better resource allocation, and enhanced responsiveness to dynamic market demands.