Challenges in Power Industry

$20 Billion

Annual Loss due to

Inefficient Energy Generation

$2 Billion

Unplanned Downtime

Cost Annually

$1.5 Billion

Asset Maintenance

Cost Annually

42%

Higher Loss Time

Injuries Annually

25%

contribution to Global

Emission Annually

Empowering Smart Energy Solutions with AI

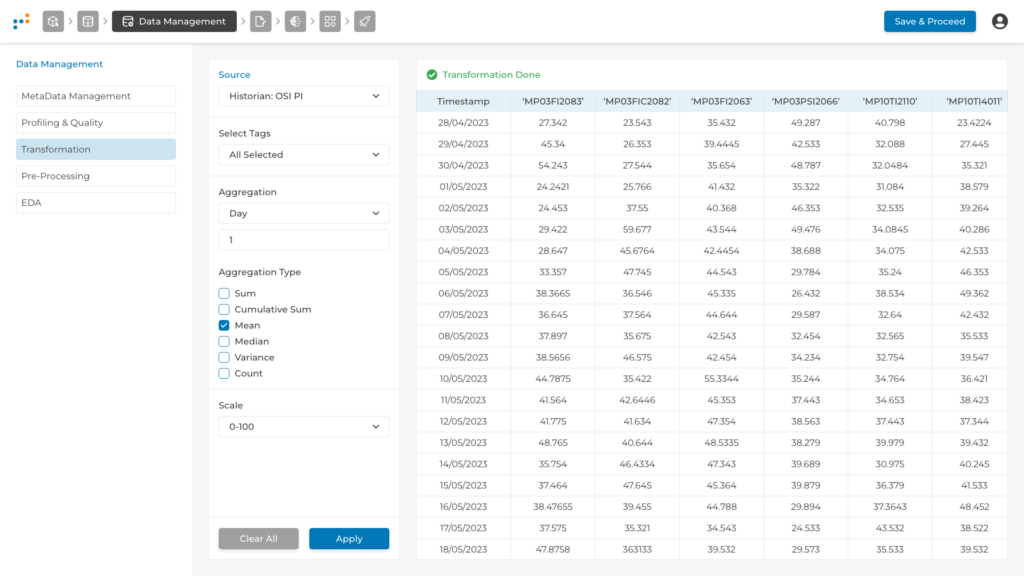

Harnessing the power of data for intelligent decision-making

- Handle the vast amounts of data generated from diverse sources

- Analyze complex patterns, and provide valuable insights

- Clean inconsistent or bad quality data

Optimizing grid operations for reliability and stability

- Predicting demand patterns

- Optimizing load distribution

- Identifying potential grid disturbances

- Enable better load balancing

- Reduce energy wastage

Optimizing grid operations for reliability and stability

- Predicting demand patterns

- Optimizing load distribution

- Identifying potential grid disturbances

- Enable better load balancing

- Reduce energy wastage

Managing equipment health and minimizing downtime

- detect equipment failures before they occur by analyzing relevant data

- schedule maintenance activities, and

- Minimize unplanned downtime, resulting in

- Improved asset performance and reduced maintenance costs.

Optimizing energy utilization

- Intelligent energy management by analyzing real-time energy data, weather forecasts, and demand patterns

- Optimize energy generation, storage, and distribution

- Improved energy efficiency, reduced operational costs & enhanced sustainability

Optimizing energy utilization

- Intelligent energy management by analyzing real-time energy data, weather forecasts, and demand patterns

- Optimize energy generation, storage, and distribution

- Improved energy efficiency, reduced operational costs & enhanced sustainability

Integrating renewable energy sources

- Managing the intermittency and variability of renewable power generation

- Forecast renewable energy output

- Optimize renewable energy integration into the grid

- Facilitate the efficient utilization of renewable resources

Safeguarding critical infrastructure

- AI can enhance grid security by detecting anomalies

- Enabling real-time response to protect critical infrastructure

Safeguarding critical infrastructure

- AI can enhance grid security by detecting anomalies

- Enabling real-time response to protect critical infrastructure

Explore what’s possible with Algo8

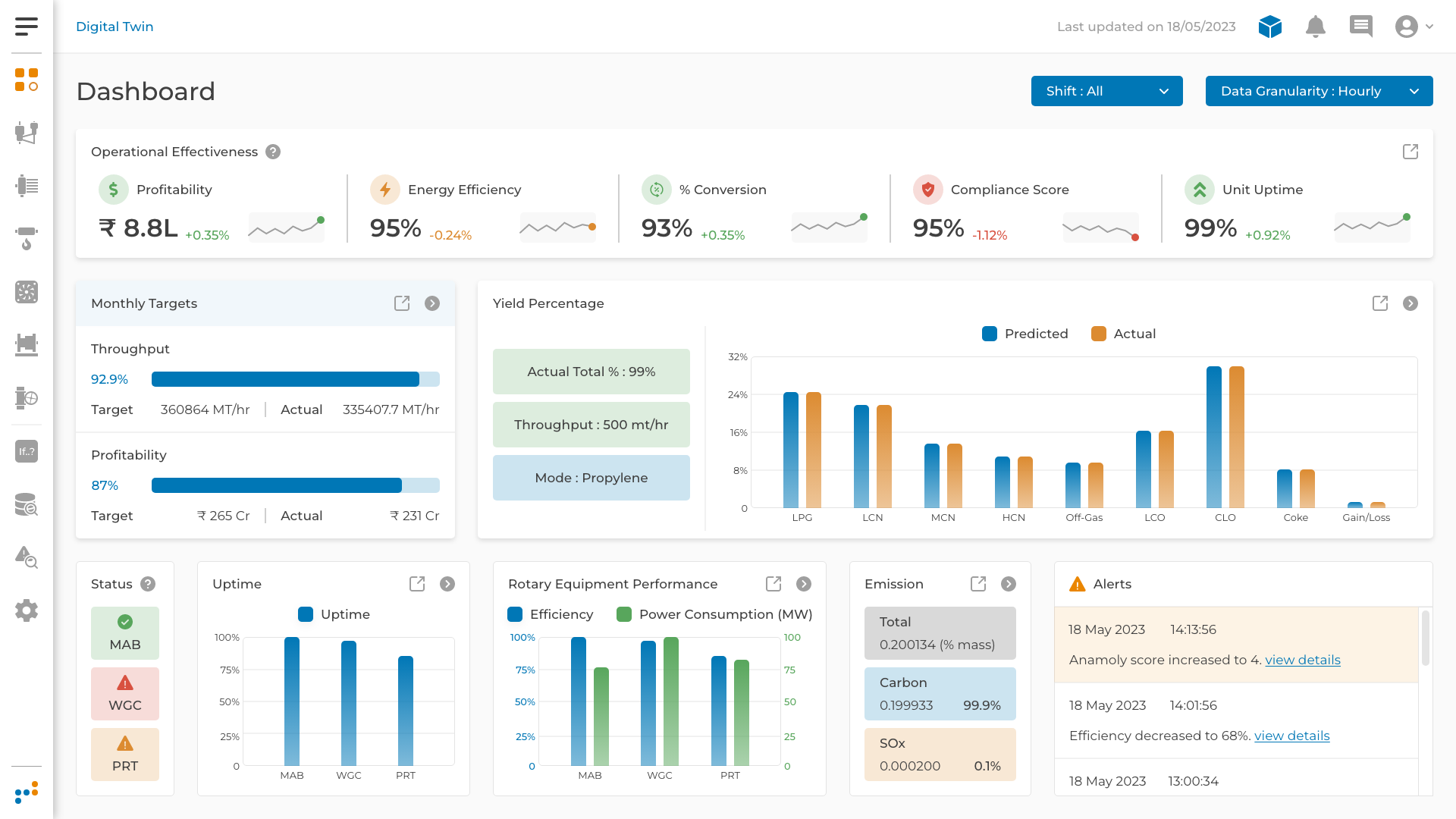

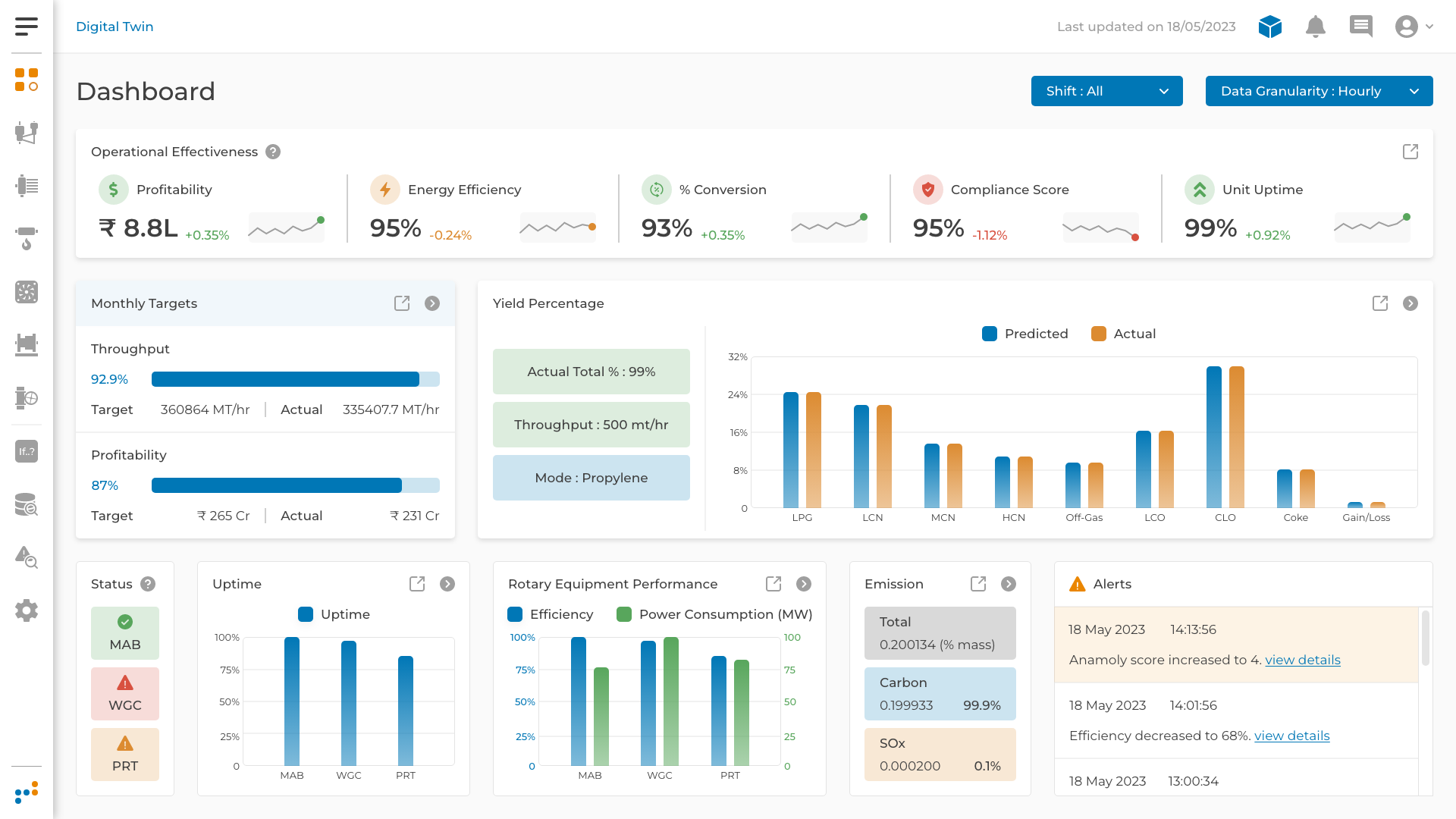

Facility & Plant Performance Monitoring

PlantBrain provides the power industry with real-time monitoring of key performance indicators (KPIs) and digital twin technology. It offers drill-down and diagnosis features to identify areas for improvement in plant performance, ensuring efficient power generation, reducing downtime, and optimizing resource utilization.

Production & Schedule Optimization

PlantBrain advanced capabilities empower the power industry to optimize production efficiency and adapt to changing demand. It ensures smoother scheduling and minimizes the impact of unexpected events on power generation, leading to improved plant productivity.

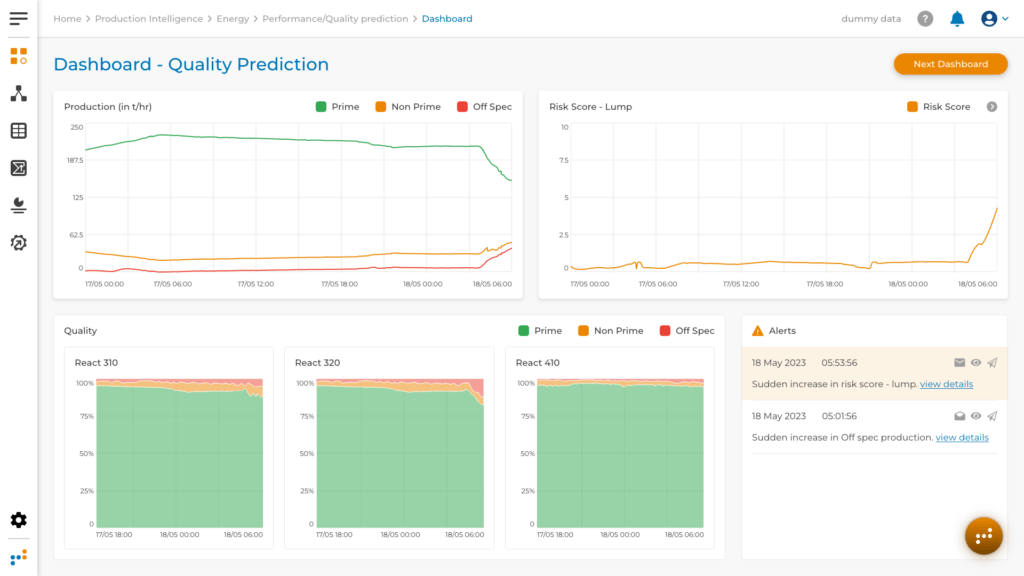

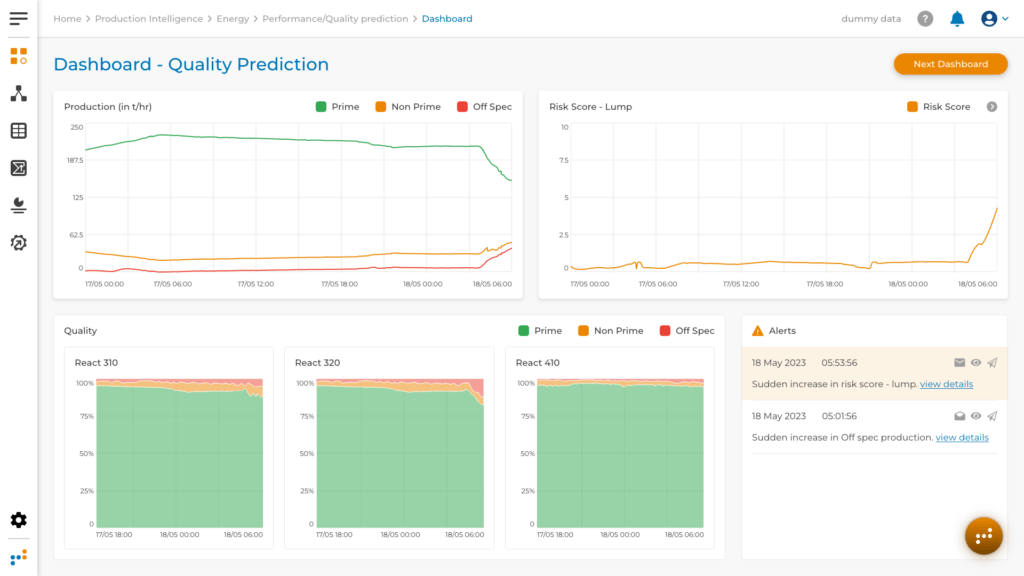

Performance & Quality Prediction

PlantBrain’s Hybrid Plant model, combined with AI Optimizer, enables the power industry to predict and optimize plant performance within operating constraints. It ensures peak efficiency, maximum energy production, and better adherence to quality standards.

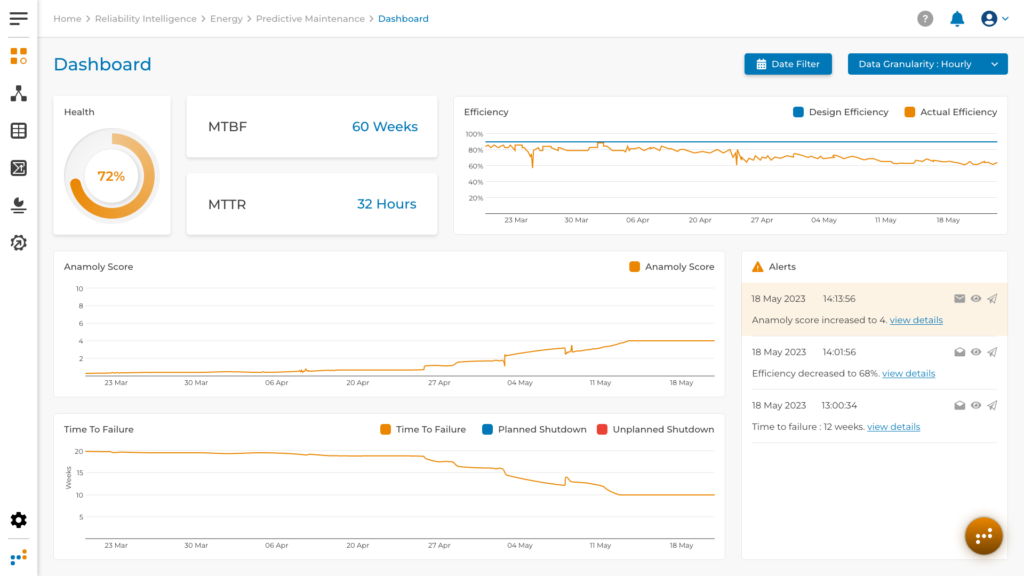

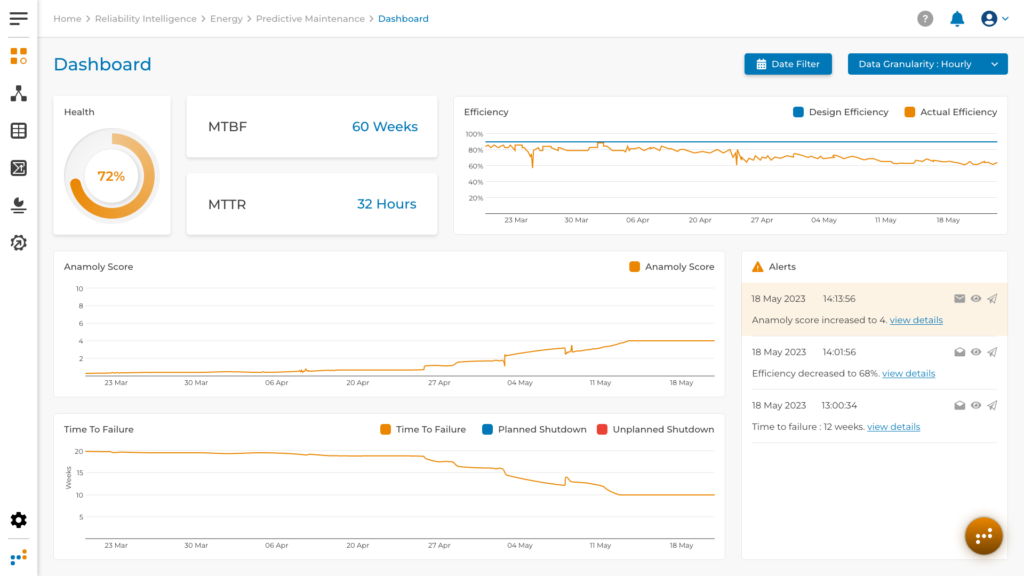

Condition Monitoring

The power industry benefits from advanced monitoring techniques and sensors that continuously assess equipment condition. It enables early detection of potential issues, reducing the risk of unexpected failures and optimizing maintenance schedules.

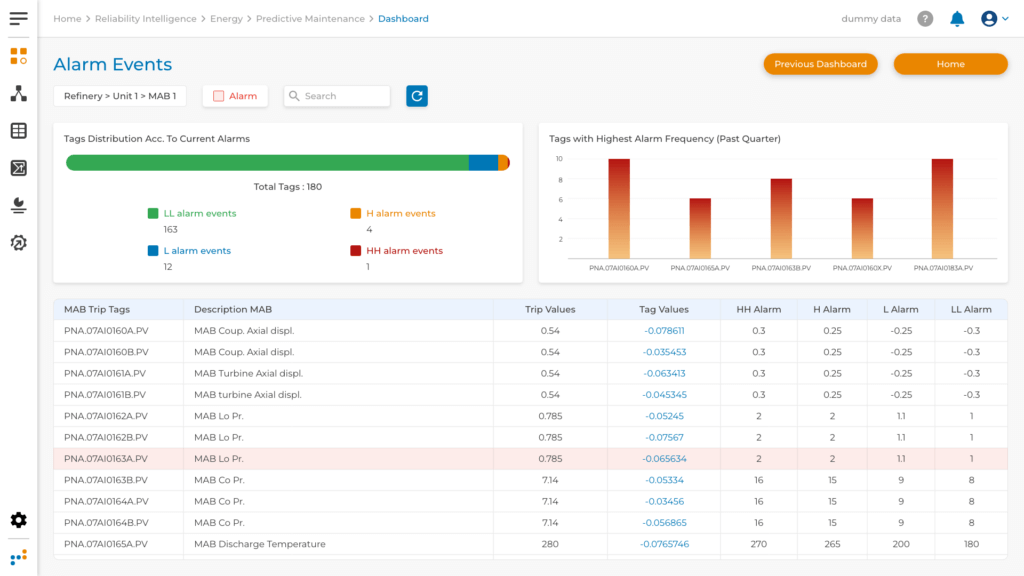

Predictive Maintenance

Predictive maintenance in the power industry utilizes data analytics and machine learning algorithms to forecast equipment failures and maintenance needs. This approach minimizes unplanned downtime, reduces maintenance costs, and ensures smooth power generation.

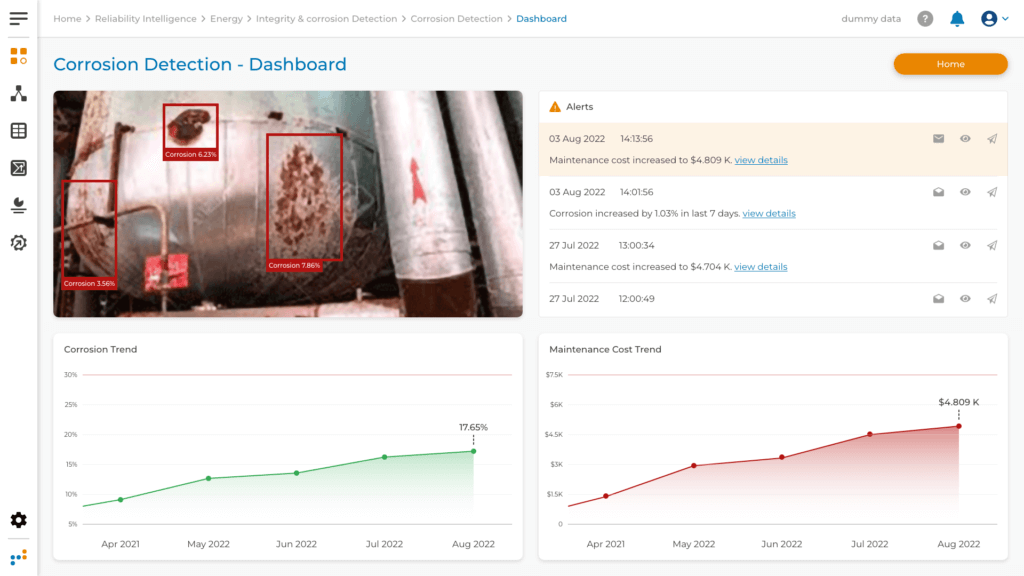

Integrity & Corrosion Detection

Integrity and corrosion detection in the power industry involves monitoring systems and algorithms to assess asset integrity, including pipelines and structures. Early detection of corrosion and integrity issues prevents costly failures and ensures safety and compliance.

Energy Management

Energy management in the power industry involves continuous monitoring and optimization of energy consumption. It enables efficient resource use, reduces carbon footprint, and drives cost savings.

Decarbonization

Decarbonization strategies and technologies in the power industry aim to reduce greenhouse gas emissions and transition to cleaner energy sources. It aligns with sustainability goals and regulatory requirements.

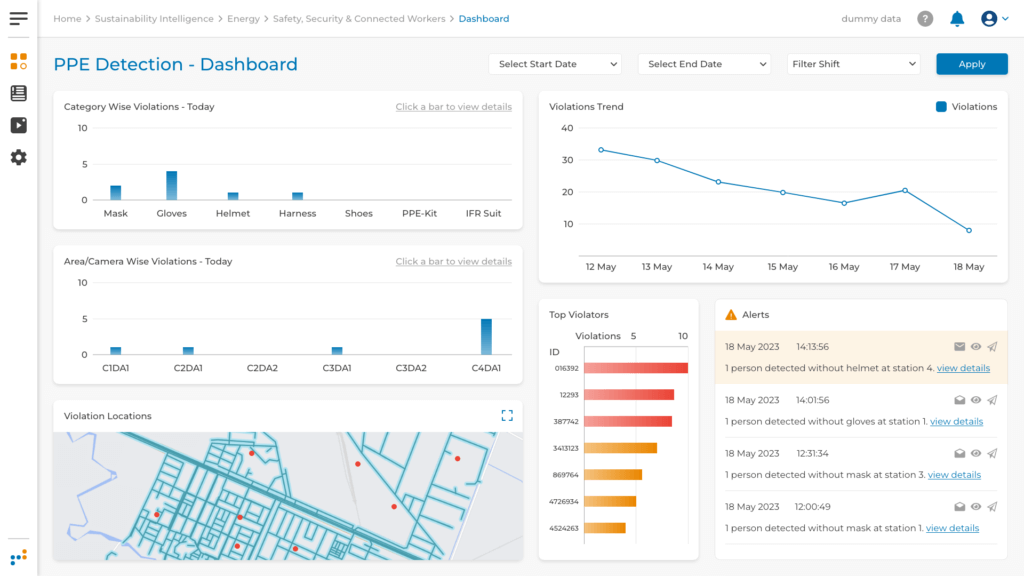

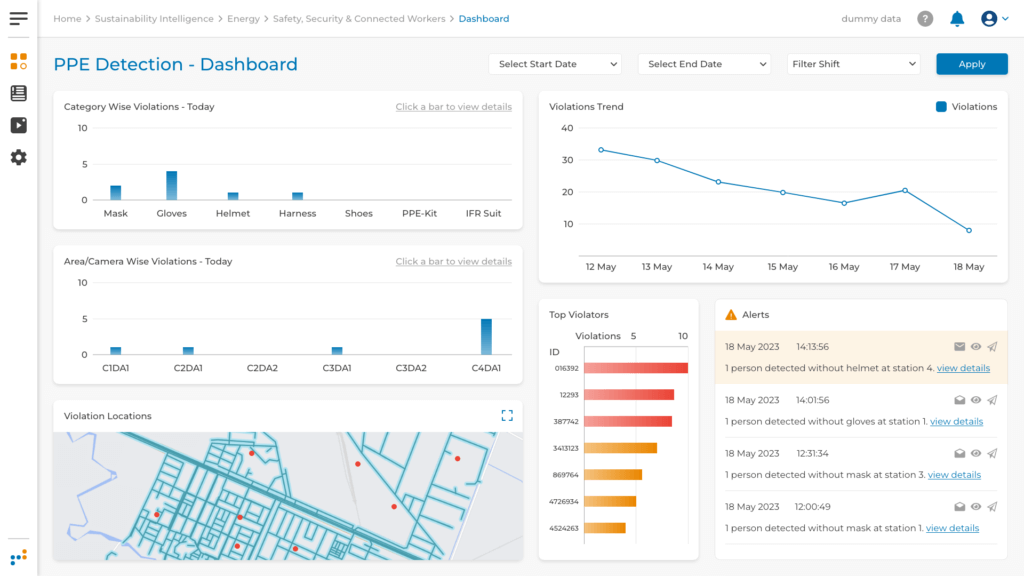

Safety, Security & Connected Workers

Safety, security, and connected worker initiatives in the power industry leverage technologies such as IoT, wearables, and real-time data analytics. They enhance incident prevention, improve response capabilities, and prioritize worker well-being.

Explore what’s possible with Algo8

Facility & Plant Performance Monitoring

PlantBrain provides the power industry with real-time monitoring of key performance indicators (KPIs) and digital twin technology. It offers drill-down and diagnosis features to identify areas for improvement in plant performance, ensuring efficient power generation, reducing downtime, and optimizing resource utilization.

Production & Schedule Optimization

PlantBrain advanced capabilities empower the power industry to optimize production efficiency and adapt to changing demand. It ensures smoother scheduling and minimizes the impact of unexpected events on power generation, leading to improved plant productivity.

Performance & Quality Prediction

PlantBrain’s Hybrid Plant model, combined with AI Optimizer, enables the power industry to predict and optimize plant performance within operating constraints. It ensures peak efficiency, maximum energy production, and better adherence to quality standards.

Condition Monitoring

The power industry benefits from advanced monitoring techniques and sensors that continuously assess equipment condition. It enables early detection of potential issues, reducing the risk of unexpected failures and optimizing maintenance schedules.

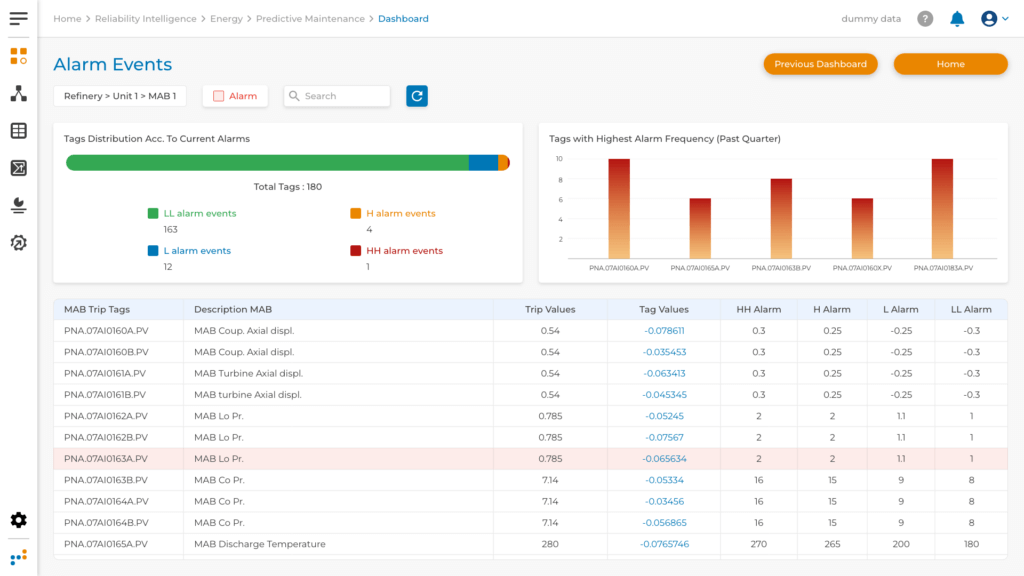

Predictive Maintenance

Predictive maintenance in the power industry utilizes data analytics and machine learning algorithms to forecast equipment failures and maintenance needs. This approach minimizes unplanned downtime, reduces maintenance costs, and ensures smooth power generation.

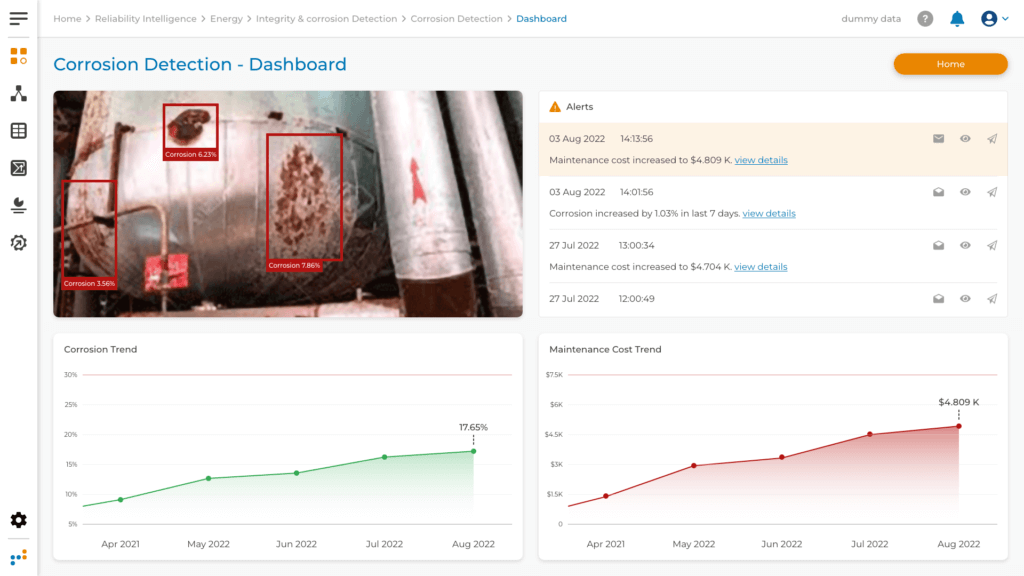

Integrity & Corrosion Detection

Integrity and corrosion detection in the power industry involves monitoring systems and algorithms to assess asset integrity, including pipelines and structures. Early detection of corrosion and integrity issues prevents costly failures and ensures safety and compliance.

Energy Management

Energy management in the power industry involves continuous monitoring and optimization of energy consumption. It enables efficient resource use, reduces carbon footprint, and drives cost savings.

Decarbonization

Decarbonization strategies and technologies in the power industry aim to reduce greenhouse gas emissions and transition to cleaner energy sources. It aligns with sustainability goals and regulatory requirements.

Safety, Security & Connected Workers

Safety, security, and connected worker initiatives in the power industry leverage technologies such as IoT, wearables, and real-time data analytics. They enhance incident prevention, improve response capabilities, and prioritize worker well-being.

Hear it from Our Clients

Hindalco

The Algo8 team implemented a successful digital solution that transformed our perception of Coal Procurement at Aditya Aluminium. Their time-series models for real-time parameters like GCV improved the precision and efficiency of our Coal Chain. In 4 months, Algo8 team gave us a competitive edge, enhancing our systems and processes.

HMEL

Algo8 is working to deploy its process module to create better foresight for Operators on quality parameters for tighter control and optimised grade change over.

Kanpur Plastipack Ltd.

Really fascinated by the possibility after experiencing a first-hand solution to hard to measure problems. Super excited to onboard more AI modules from Algo8

IOCL

The technology has brought about a 360-degree turnaround that has solved the critical setbacks such as leakages, pressures, temperature, vibrations and unplanned breakdowns. We have observed op-ex cuts by reducing the failure quotient of the equipment.

A Fortune 500 Co.

General ManagerThe technology has brought about a 360-degree turnaround that has solved critical setbacks causing unplanned breakdowns. We have observed op-ex cuts by reducing the failure quotient of the equipment

A Leading Upstream O&G Co.

Business Advisor"An excellent team and an even better product. We have straight away saved $1mn in the past 6 months alone."

IOCL

COO“We have been working with Algo8 for the past 2 years. We started with 1 refinery but now have rolled out their products to 8 refineries. It has been a pleasure working with them”