EOR Optimization and Polymer Injection Reduction for Upstream Oil & Gas Operator

Problem

The upstream oil and gas operator uses Polymer Enhanced Oil Recovery (EOR) to improve the sweep efficiency of existing water flood systems. Polymer injection involves increasing the viscosity of injected water with polymers to improve sweep efficiency. However, maintaining the right viscosity at the wellhead level presents several challenges:

- Viscosity Loss in Pipelines: The polymer solution experiences viscosity loss as it travels through pipelines from the centralized preparation facility to the wellhead. This leads to variations in the target viscosity at the injection points.

- Lack of Visibility in Dilution Ratio: Maintaining the right dilution ratio of the polymer solution at the wellhead becomes challenging due to lack of real-time visibility and monitoring.

- Limited Laboratory Testing: The remote location of multiple wells makes it difficult to perform lab testing of wellhead viscosity on a shift basis, leading to difficulties in adjusting injection rates.

Approach

To address the challenges in polymer injection and improve EOR optimization, the upstream oil and gas operator can implement the following approach:

- Real-Time Monitoring and Data Collection: Install sensors and monitoring devices along the pipelines to track the viscosity and other relevant parameters of the polymer solution in real-time. Gather data on flow rates, pressure, and temperature at various points to understand the viscosity loss during transportation.

- IoT Connectivity and Data Integration: Utilize IoT technology to connect the monitoring devices and sensors to a centralized data platform. Integrate the real-time data with reservoir and geo data from the wells for a comprehensive understanding of the injection process.

- Machine Learning Models: Develop machine learning models that analyze the real-time data and predict the viscosity at the wellhead based on historical patterns and pipeline characteristics. These models can adjust the target viscosity based on real-time conditions.

- Automated Injection Adjustment: Implement an automated control system that adjusts the injection rates at the wellhead to maintain the desired viscosity level. The control system can take inputs from the machine learning models and dynamically adjust the polymer injection rates.

- Remote Monitoring and Control: Enable remote monitoring and control of the polymer injection process from a central control room. Operators can access real-time data, make adjustments, and optimize injection rates without the need for on-site visits.

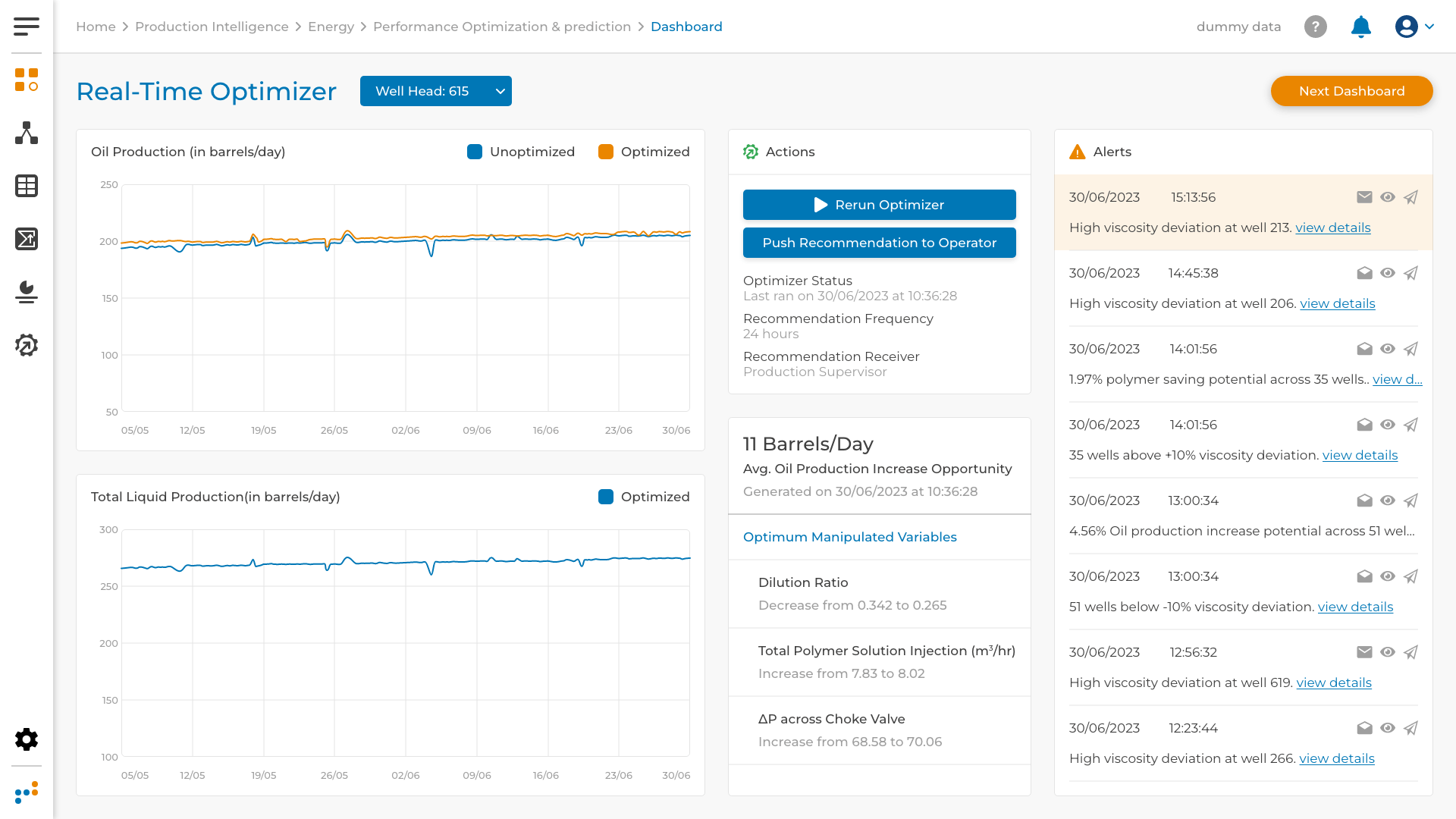

- Data Visualization and Reporting: Develop a data visualization and reporting dashboard that provides a clear overview of the injection process, including real-time viscosity, injection rates, and efficiency. This allows for informed decision-making and performance analysis.

Benefit

- Optimized Polymer Injection: The real-time monitoring and automated control system ensure that the right viscosity is maintained at the wellhead, leading to improved sweep efficiency and enhanced EOR optimization.

- Reduced Polymer Consumption: With better control over polymer injection rates, the operator can reduce polymer consumption, resulting in cost savings and improved overall operational efficiency.

- Enhanced Visibility and Efficiency: The IoT connectivity and data integration provide better visibility into the injection process, allowing for more efficient decision-making and troubleshooting.

- Minimized Downtime: Proactive adjustments based on real-time data help minimize downtime caused by viscosity variations, leading to continuous and stable injection operations.

- Remote Operations: Remote monitoring and control capabilities enable efficient management of multiple wells from a centralized location, reducing the need for on-site visits and associated costs.

- Improved Production: By optimizing sweep efficiency and EOR operations, the operator can achieve improved oil production rates and enhanced recovery from existing wells.

In conclusion, implementing real-time monitoring, data integration, and automated control for polymer injection in EOR can lead to significant benefits, including enhanced sweep efficiency, reduced polymer consumption, and improved overall operational efficiency for the upstream oil and gas operator.