Rotating Equipment Condition Monitoring Maintenance & Fault Prediction using Wireless Sensors

Problem

An industrial conglomerate faced challenges with their existing maintenance practices for rotating equipment, particularly screw compressors and their motors. Despite regular preventive maintenance processes and periodic vibration analyses, the company experienced a year-over-year increase in equipment failures. The delays in procuring components for rebuilding further complicated the situation. The traditional inspection regime did not yield the intended results, and the company needed a more effective and proactive approach to prevent failures and optimize maintenance.

Approach

To address the challenges and enhance equipment maintenance, the company adopted a Condition Monitoring Maintenance (CMM) application with wireless sensors and AI-based analytics. The following approach was implemented:

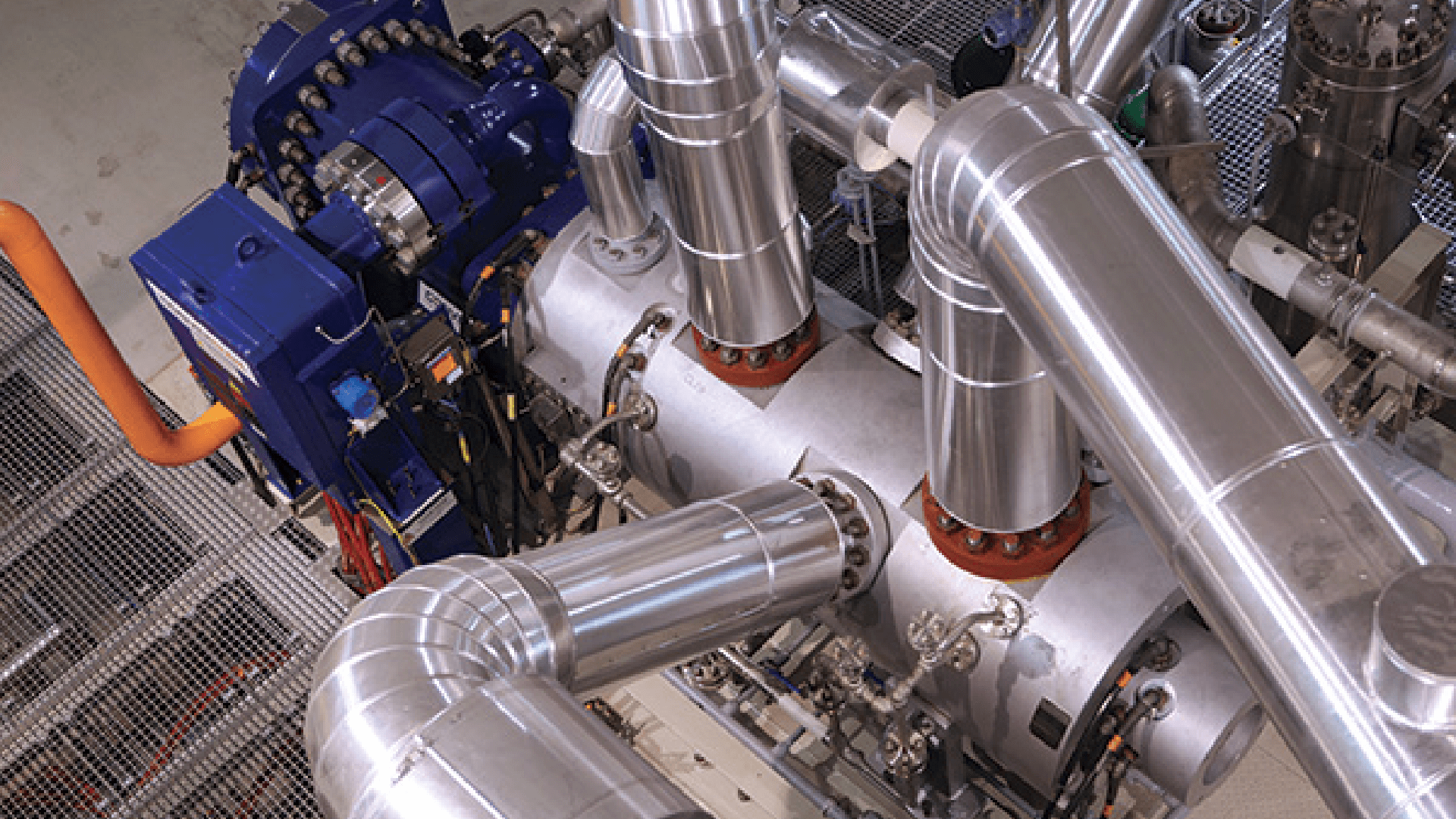

- Smart Wireless Sensors: Proprietary wireless sensors were installed on multiple refrigeration chillers, each comprising a 500HP AC motor driving an 800-ton Frick ammonia twin screw compressor. These sensors continuously monitor tri-axis vibration and temperature data from the rotating equipment.

- AI + Physics-based Analytics: The CMM application utilizes AI and physics-based analytics models developed by Algo8 to analyze the vibration and temperature data in real-time. The AI model learns from the collected data to create an evolving condition map of the equipment across its operating range.

- Early Fault Detection: By continuously analyzing small snippets of vibration and temperature information, the application detects anomalies and deviations from normal equipment behavior. It can predict potential failure modes and provides actionable insights for timely corrective actions.

- Real-time Alerts: The CMM application immediately alerts the maintenance team through the app and email when it identifies increasing overall vibration levels and an increasing noise floor, indicating potential issues with the equipment.

Benefit

The implementation of the CMM application with wireless sensors and AI-based analytics yielded significant benefits:

- Cost Savings: The early detection of potential failures and condition-based maintenance allowed the company to save 90% of direct costs associated with rebuilding, including rigging and labor expenses.

- Avoided Downtime and Production Loss: By identifying issues early, the application helped the company avoid unplanned downtime of 3 hours and prevented production losses during the same period.

Impact

The adoption of the CMM application resulted in notable financial benefits for the industrial conglomerate:

- Direct Cost Savings: The early detection of equipment issues and consequent cost savings amounted to $40,000, providing a greater than 10x return on investment (ROI) for the motor-compressor.

- Avoided Production Losses: Additionally, the application’s proactive approach prevented 3 hours of line downtime and production loss, resulting in further undisclosed dollar savings.

By leveraging smart wireless sensors and AI-based analytics for rotating equipment condition monitoring, the company achieved cost savings, reduced downtime, and improved maintenance efficiency, ultimately leading to enhanced operational reliability and profitability.