Real-Time Tracking of Worker and Machine Availability with Computer Vision and IoT Sensors

Problem

In industries such as manufacturing, logistics, and construction, efficient management of human resources and machinery is crucial for optimizing operations. However, manual tracking of worker and machine availability can be time-consuming, error-prone, and lacks real-time visibility. This can lead to inefficiencies, delays, and increased costs. The challenge is to develop a system that automates the tracking process and provides accurate, real-time data on worker and machine availability and status.

Approach

The solution involves leveraging computer vision and IoT sensors to collect and analyze data about worker and machine movements and statuses in real-time. Here’s an overview of the key components and steps in the approach:

- Camera Network Deployment: Install cameras strategically throughout the facility or work environment to capture visual data of workers and machines’ locations and movements. These cameras can be fixed, PTZ (pan-tilt-zoom), or even wearable devices on workers.

- IoT Sensor Integration: Equip machines and tools with IoT sensors capable of tracking their operational status, such as whether they are active, idle, or undergoing maintenance.

- Data Collection: The cameras and IoT sensors continuously gather data, which includes worker locations, movements, machine statuses, and timestamps. This data is then sent to a central data repository.

- Computer Vision Algorithms: Utilize computer vision algorithms to process the visual data from the cameras. These algorithms can perform tasks such as object detection (identifying workers and machines), tracking (monitoring their movements), and gesture recognition (identifying specific actions or activities).

- IoT Sensor Data Analysis: Analyze the data from IoT sensors to determine the operational status of machines and tools. This could involve identifying periods of downtime, maintenance requirements, or other relevant insights.

- Data Fusion: Combine the information gathered from computer vision and IoT sensors to get a comprehensive view of worker and machine availability and performance.

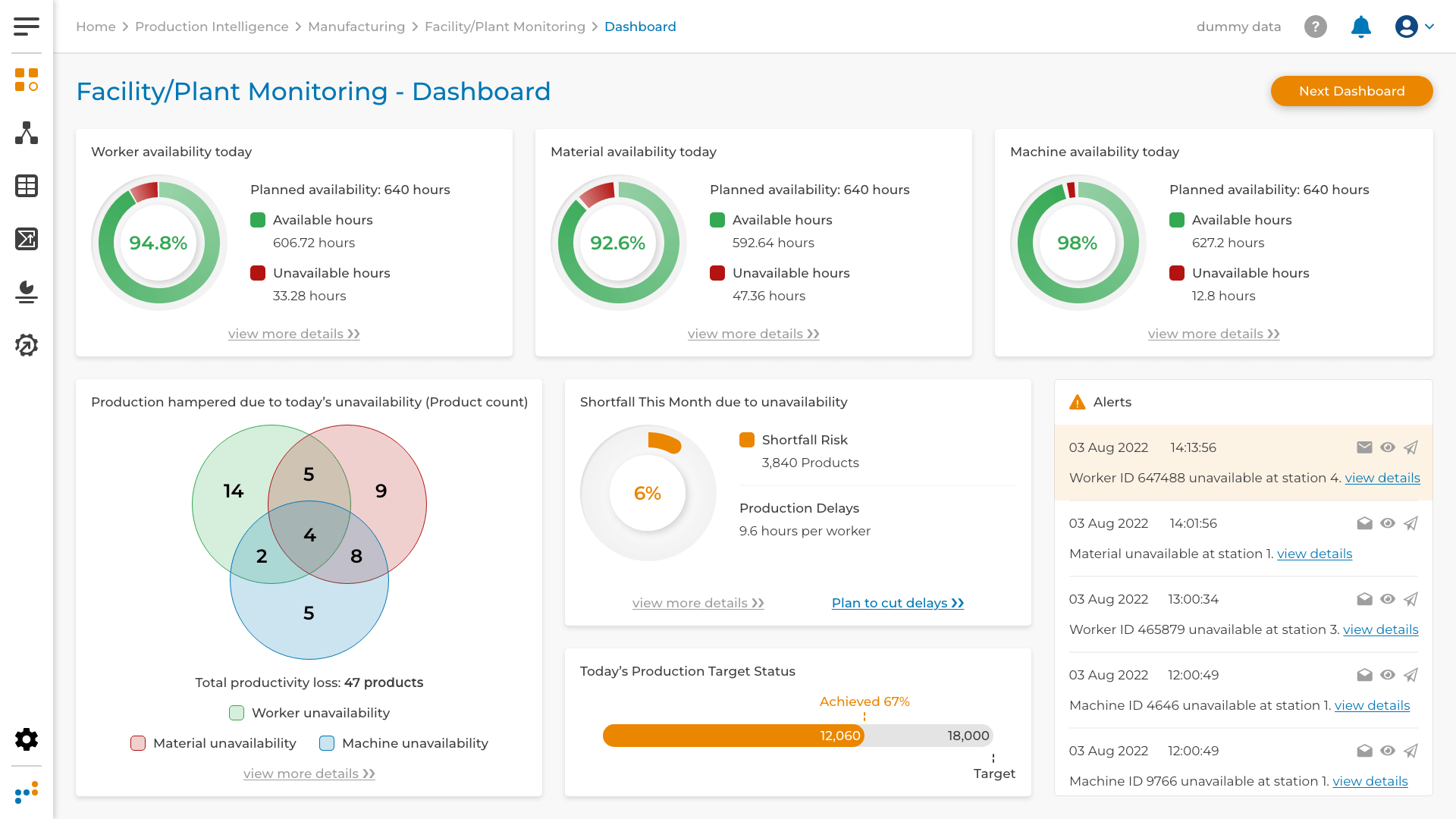

- Real-Time Dashboard: Develop a user-friendly dashboard that displays the real-time status of workers and machines, providing a clear overview of their availability and performance metrics. Managers can access this dashboard from any connected device.

- Alerts and Notifications: Implement an alerting system that notifies managers or supervisors of any issues or bottlenecks. For instance, if a critical machine experiences a failure or if there are potential safety concerns due to worker movements, the system can send immediate notifications.

Benefit

- Enhanced Productivity: Real-time tracking provides managers with instant insights into worker and machine availability, enabling them to assign tasks efficiently and reduce downtime.

- Optimized Resource Allocation: With accurate availability data, managers can allocate workers and machines more effectively, streamlining operations and reducing idle time.

- Improved Safety and Compliance: The system can monitor and alert in case of safety violations, preventing accidents and ensuring compliance with safety protocols.

- Data-Driven Decision Making: Access to real-time data and historical trends empowers managers to make informed decisions and implement process improvements based on objective data.

- Cost Savings: By minimizing downtime and optimizing resource allocation, businesses can reduce operational costs and maximize overall efficiency.

- Predictive Maintenance: Analysis of IoT sensor data can reveal patterns that indicate when machines might need maintenance, allowing for proactive maintenance planning and avoiding costly breakdowns.

- Process Optimization: The insights gained from data analysis can highlight inefficiencies in the workflow, enabling businesses to make targeted improvements and increase overall productivity.

- Remote Monitoring: Managers can monitor operations and make decisions remotely, leading to better resource management even when physically absent from the site.

By combining computer vision and IoT sensors to track worker and machine availability in real-time, businesses can achieve greater visibility into their operations, optimize processes, enhance safety, and ultimately increase overall efficiency and profitability.