About PlantBrain

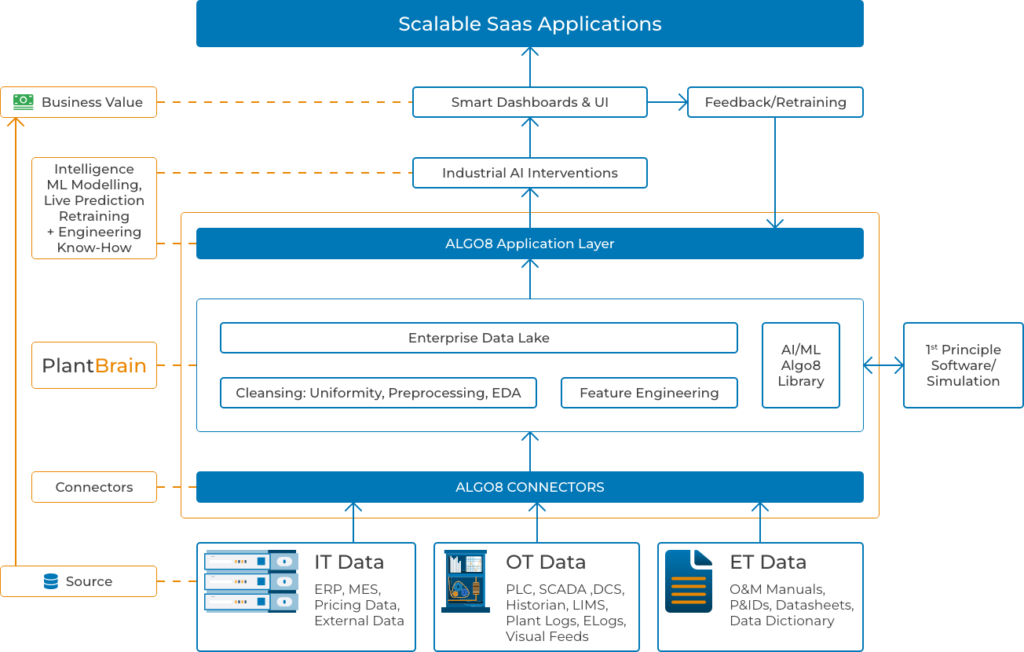

Our platform “PlantBrain” leverages AI/ML to learn deeply and uniquely from the data of each schedule, process, asset, conversations and optics, creating algorithmic twins of your operations.

By leveraging advanced analytics, machine learning algorithms, and other AI tools, PlantBrain enables operators to make data-driven decisions that can drive significant improvements in efficiency, reliability, profitability, and safety.

What we can help you achieve

Upto 10%

Increase in Throughput

Upto 80%

Less Unplanned Downtime

![Project_74-06 [Converted]-02](https://algo8.ai/wp-content/uploads/2023/06/Project_74-06-Converted-02.png)

Upto 6%

Improvement in Prime Quality Production

Upto 90%

Reduction in Manual Inspection

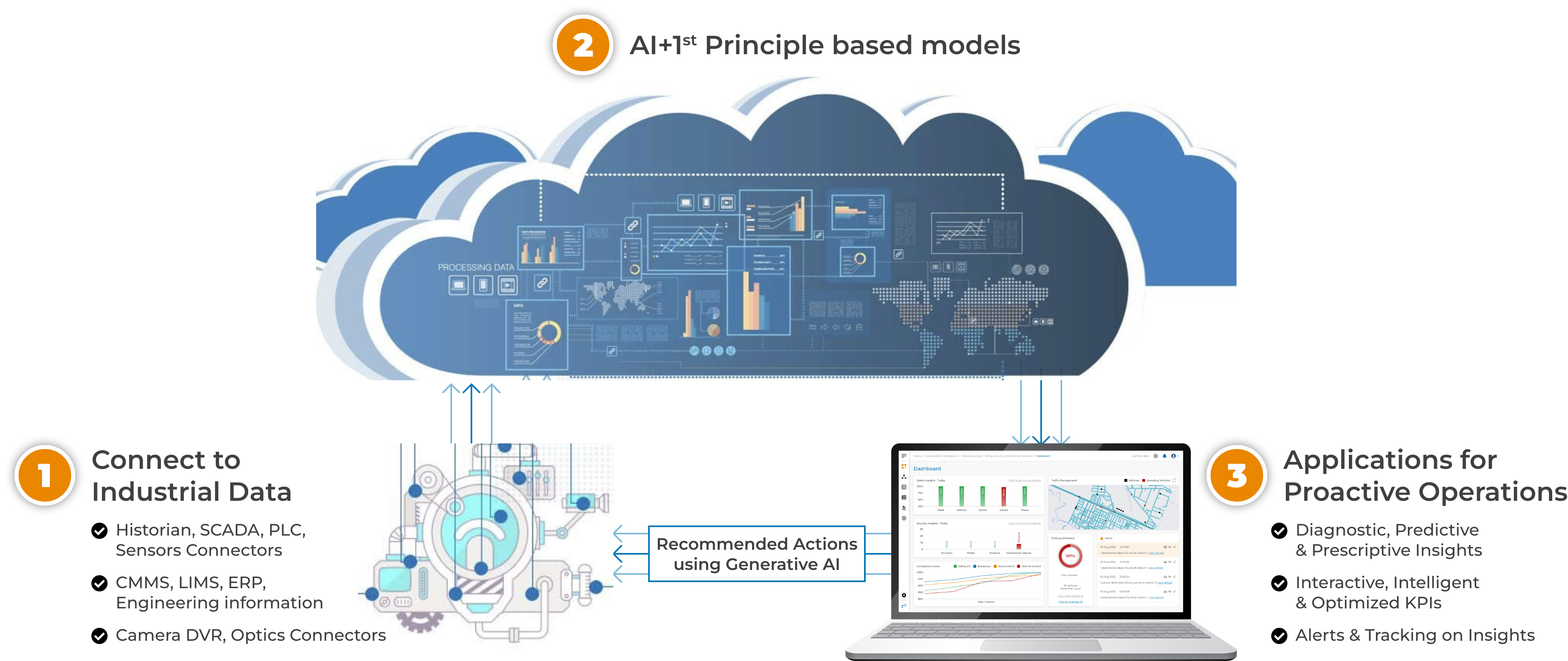

How PlantBrain works

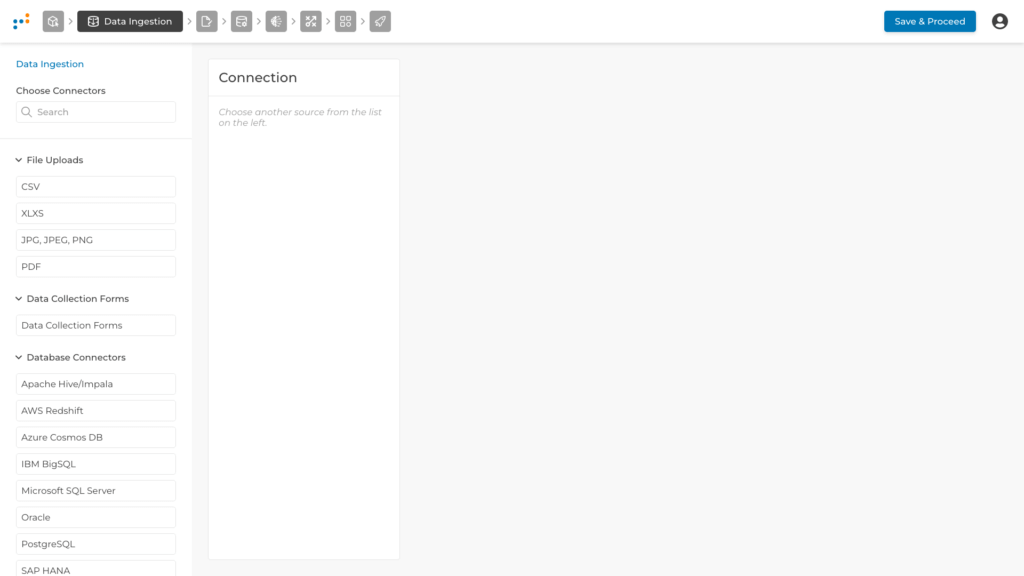

Rapid integration on Industrial Data

- The Industrial AI platform PlantBrain, begins by ingesting data from various sources, including Historian, SCADA, PLC, Sensors Connectors, CMMS, LIMS, ERP, Engineering information, Camera DVR, Optics Connectors, and other structured or unstructured data repositories.

- This data ingestion process involves connecting to the data sources, retrieving the relevant data, and transferring it to the platform for further processing.

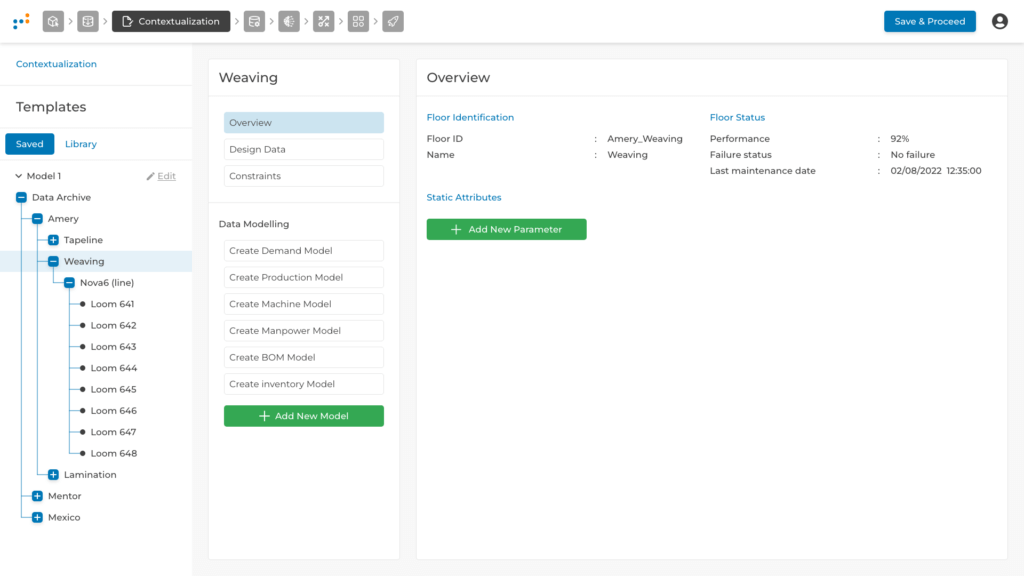

Construction of Contextualized Industrial Data Lakehouse

- PlantBrain manages and organizes it in a structured manner. This includes storing the data in a centralized repository, such as a contextualized industrial data lakehouse, ensuring efficient data storage and retrieval.

- Data management also involves implementing security measures to protect sensitive data, ensuring data integrity and compliance with data governance policies.

Embedded Business Requirements and Engineering Expertise

- AI applications are embedded with the specific business requirements and goals of the organization.

- Incorporate engineering first principles and expertise into the design and configuration of the applications.

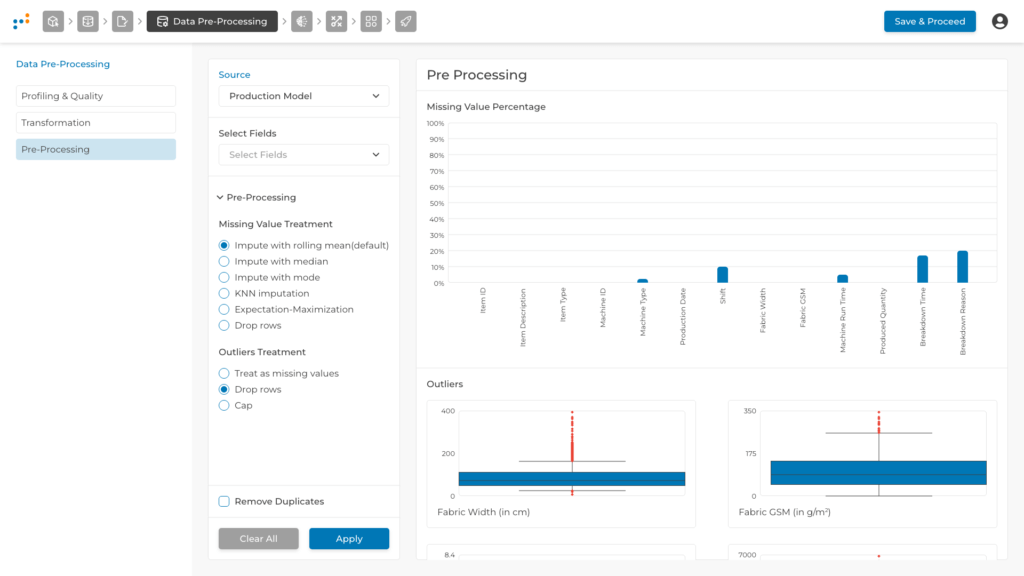

Data Cleaning and Preprocessing

- Identifying and handling missing data, dealing with outliers or noise, and addressing data inconsistencies or errors.

- Data preprocessing techniques like data normalization, feature scaling, or dimensionality reduction, may be applied to optimize the data for analysis and modeling.

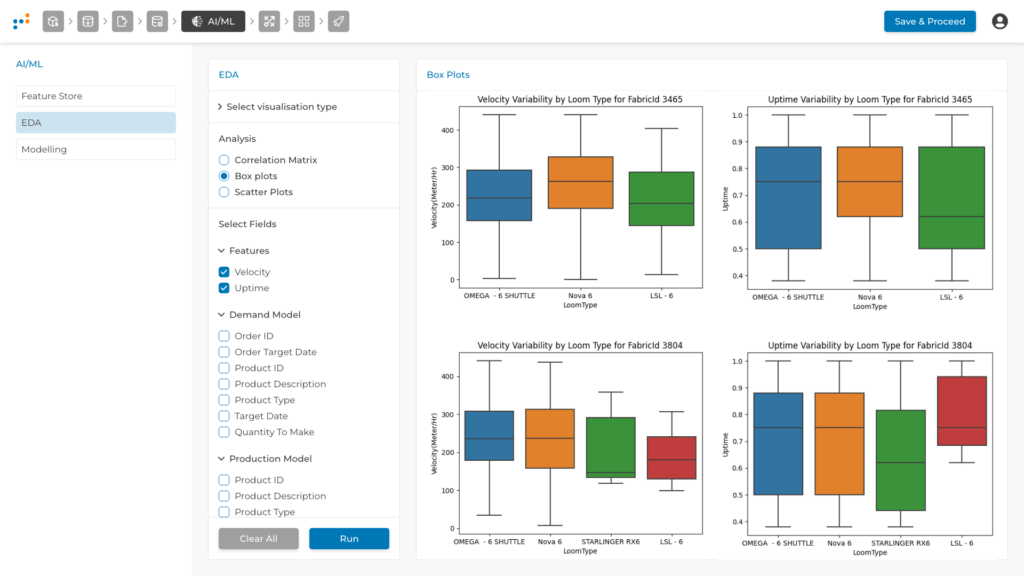

Exploratory Data Analysis (EDA)

- PlantBrain performs exploratory analysis to gain insights into the data. This involves statistical analysis, data visualization, and data profiling to understand the characteristics, distributions, correlations, and patterns within the data.

- EDA helps identify trends, anomalies, or potential relationships between variables, guiding subsequent analysis and modeling processes.

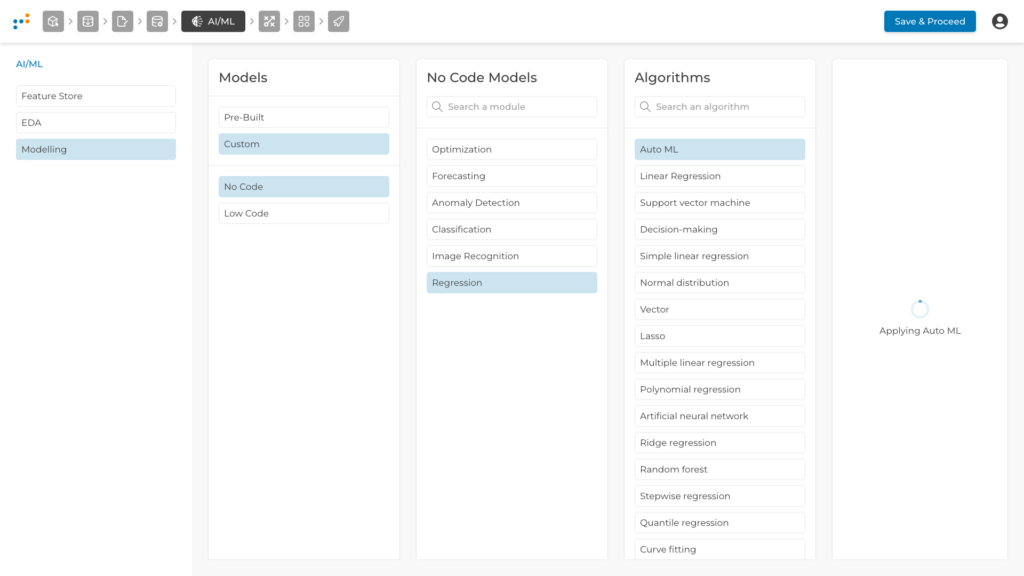

AI Modeling

- PlantBrain employs AI modeling techniques to extract valuable insights and build predictive or prescriptive models. This step includes various processes, such as feature engineering, algorithm selection, model training, and model evaluation.

- Feature engineering involves selecting or creating relevant features from the data to feed into the AI models, enhancing their predictive capabilities.

- Algorithm selection involves choosing the appropriate machine learning or deep learning algorithms that align with the specific problem and data characteristics.

- Model training utilizes historical data to train the AI models, optimizing their performance and accuracy.

- Model evaluation assesses the models' performance using evaluation metrics and validation techniques to ensure their reliability and effectiveness in generating insights.

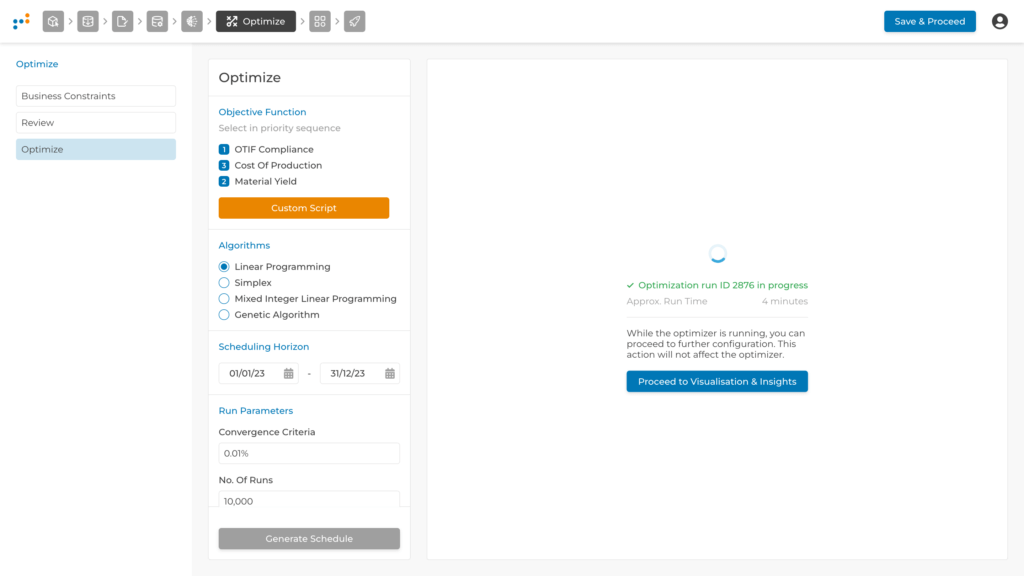

Diagnostic, Predictive, and Prescriptive Insights

- PlantBrain generates insights from the trained AI models, enabling diagnostic, predictive, and prescriptive capabilities.

- Diagnostic insights provide an understanding of the current state of the operations, identifying patterns, anomalies, or deviations from normal behavior.

- Predictive insights forecast future outcomes or trends based on historical data, enabling proactive decision-making and early identification of potential issues.

- Prescriptive insights offer recommendations or optimization strategies to improve operations, guiding decision-making processes to achieve desired outcomes.

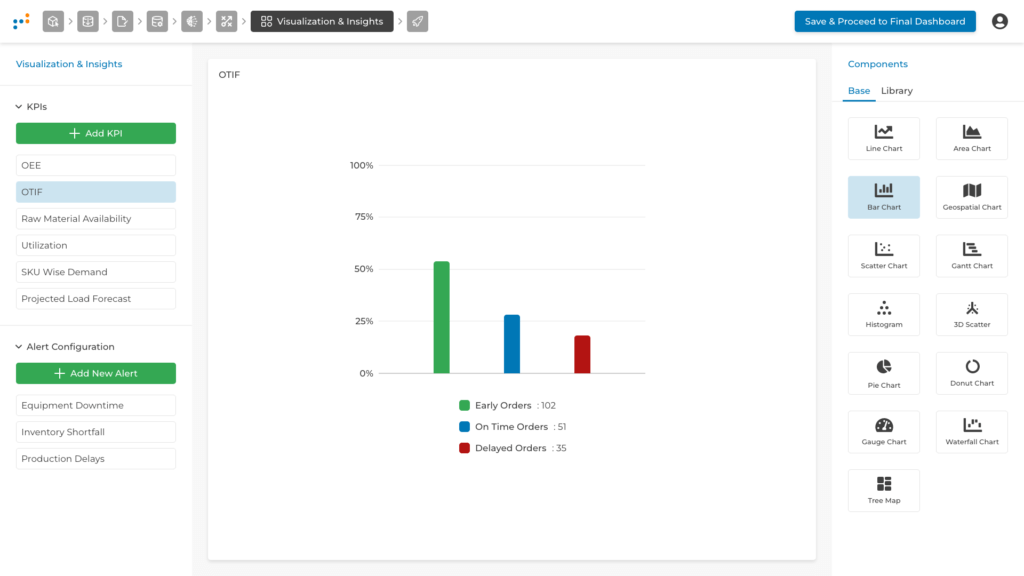

Interactive, Intelligent & Optimized KPIs, Alerts, and Tracking

- PlantBrain provides interactive and intelligent visualizations of Key Performance Indicators (KPIs), allowing stakeholders to monitor and track operational performance in real-time.

- The platform also incorporates alert mechanisms to notify stakeholders about critical events, anomalies, or deviations from desired performance.

- Additionally, the platform offers tracking capabilities to monitor the progress of insights, actions taken, and the impact on operational performance.

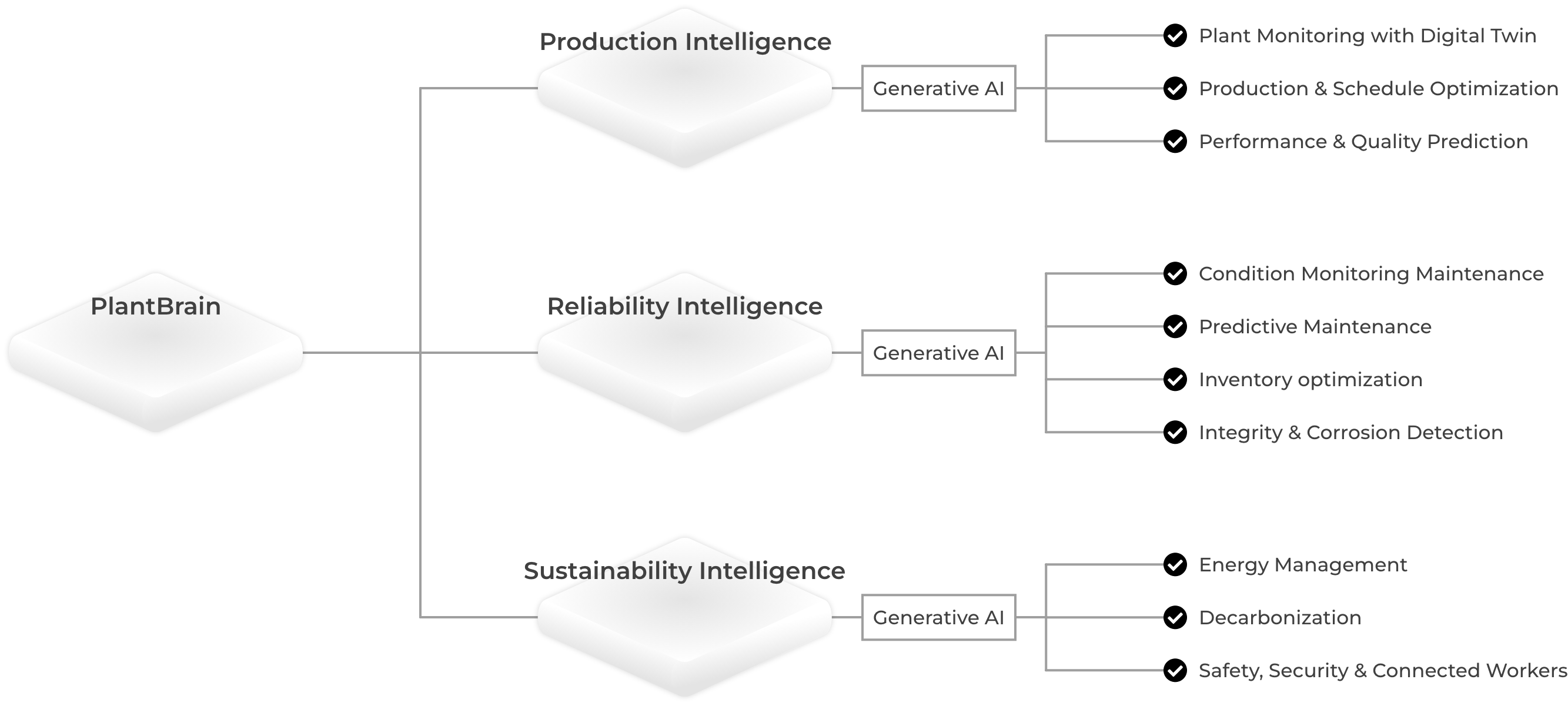

Products

Production Intelligence

Gain real-time insights, optimize performance, and maximize efficiency.

Read More

Reliability Intelligence

Keep your operations running smoothly and efficiently with Algo8 AI’s Reliability intelligence solutions.

Read More

Sustainability Intelligence

Maximize resource efficiency, minimize environmental impact, and pave the way for a sustainable future.

Read MoreApplicable Industries

Hear it from Our Clients

Hindalco

The Algo8 team implemented a successful digital solution that transformed our perception of Coal Procurement at Aditya Aluminium. Their time-series models for real-time parameters like GCV improved the precision and efficiency of our Coal Chain. In 4 months, Algo8 team gave us a competitive edge, enhancing our systems and processes.

HMEL

Algo8 is working to deploy its process module to create better foresight for Operators on quality parameters for tighter control and optimised grade change over.

Kanpur Plastipack Ltd.

Really fascinated by the possibility after experiencing a first-hand solution to hard to measure problems. Super excited to onboard more AI modules from Algo8

IOCL

The technology has brought about a 360-degree turnaround that has solved the critical setbacks such as leakages, pressures, temperature, vibrations and unplanned breakdowns. We have observed op-ex cuts by reducing the failure quotient of the equipment.

A Fortune 500 Co.

General ManagerThe technology has brought about a 360-degree turnaround that has solved critical setbacks causing unplanned breakdowns. We have observed op-ex cuts by reducing the failure quotient of the equipment

A Leading Upstream O&G Co.

Business Advisor"An excellent team and an even better product. We have straight away saved $1mn in the past 6 months alone."

IOCL

COO“We have been working with Algo8 for the past 2 years. We started with 1 refinery but now have rolled out their products to 8 refineries. It has been a pleasure working with them”