Heat Exchangers Fouling Prediction and Cleaning Schedule Optimization

Problem

The refining and chemical industries face a significant challenge with heat exchanger fouling, where deposits of impurities accumulate on heat exchanger surfaces over time. This fouling reduces heat transfer efficiency, leading to several issues:

- Increased CO2 Emissions: Reduced heat transfer efficiency requires higher energy consumption, leading to increased greenhouse gas emissions and environmental impact.

- Decreased Plant Profitability: Heat exchanger fouling leads to reduced production throughput and increased energy costs, affecting the overall profitability of the plant.

- Higher Maintenance Costs: Frequent fouling requires more frequent cleaning, leading to increased downtime and maintenance expenses.

- Energy Consumption: Infrequent cleaning results in limited heat transfer capabilities, leading to higher energy consumption to achieve the desired process temperatures.

Approach

To address the challenges of heat exchanger fouling and optimize the cleaning schedule, the following approach can be implemented:

- Data Collection and Monitoring: Install sensors on heat exchangers to continuously monitor key parameters, such as temperature, pressure, flow rates, and fouling indicators (e.g., pressure drop). Collect historical data on fouling patterns and cleaning schedules.

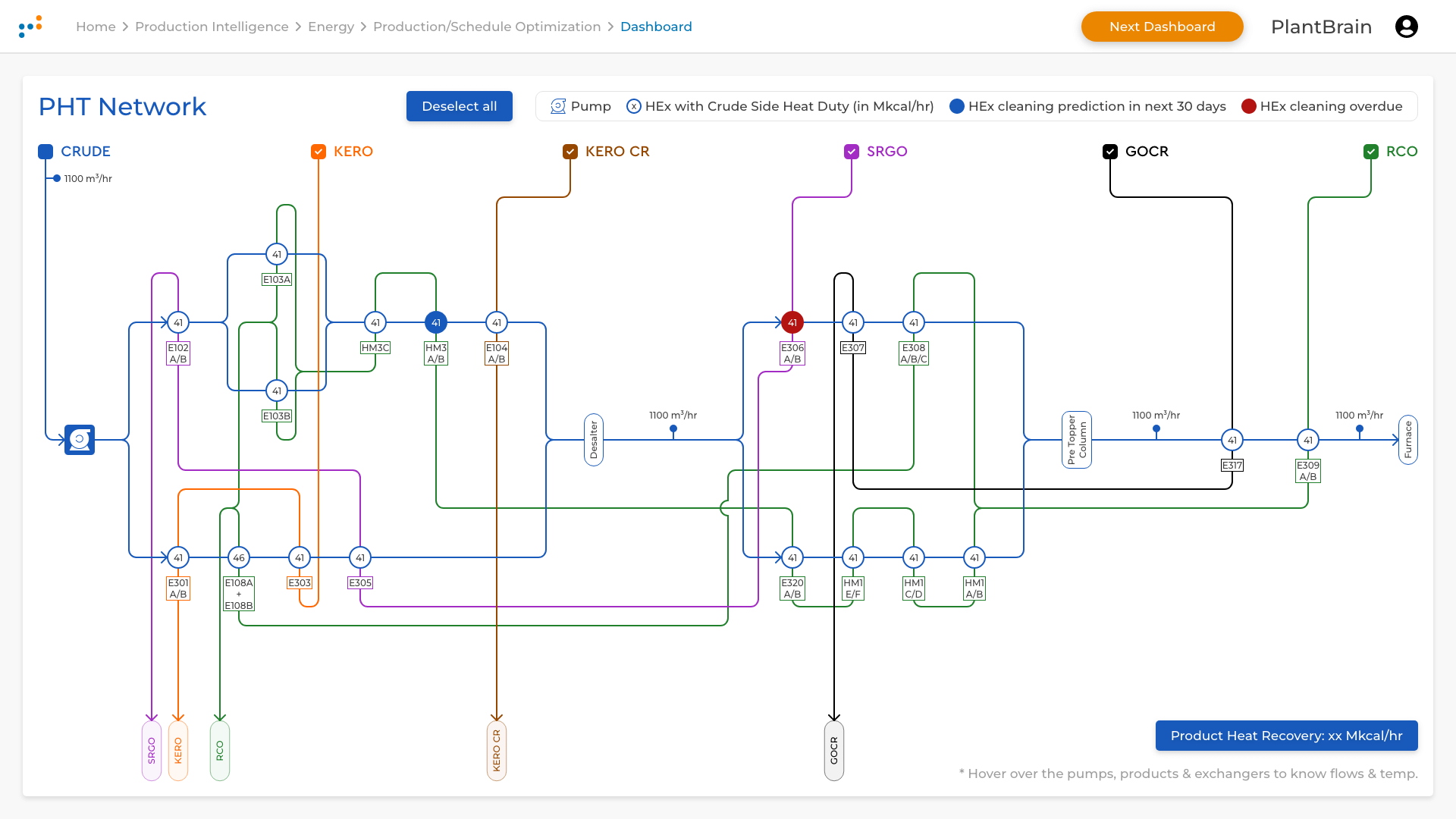

- Machine Learning for Fouling Prediction: Utilize machine learning algorithms to analyze the sensor data and predict fouling tendencies. The models can identify early signs of fouling and estimate the rate of fouling accumulation for each heat exchanger.

- Cleaning Cost Analysis: Analyze the cost associated with heat exchanger cleaning, considering factors like cleaning materials, labor, downtime, and energy consumption during the cleaning process.

- Optimization Algorithm: Develop an optimization algorithm that balances the trade-off between cleaning frequency and energy consumption. The algorithm considers factors such as fouling prediction, cleaning cost, energy savings due to improved heat transfer, and operational constraints.

- Real-Time Cleaning Decision Support: Implement a real-time decision support system that takes input from the fouling prediction models and optimization algorithm. The system recommends the most cost-effective cleaning schedule for each heat exchanger based on real-time conditions.

- Condition-Based Cleaning: Move from a fixed schedule-based cleaning approach to a condition-based cleaning strategy. Clean the heat exchangers only when the fouling accumulation reaches a predetermined threshold, optimizing cleaning efforts and reducing unnecessary downtime.

- Continuous Learning: Continuously update and improve the machine learning models based on new data to enhance fouling prediction accuracy over time.

Benefit

- Improved Heat Exchanger Performance: The prediction of fouling tendencies and optimized cleaning schedule leads to improved heat transfer efficiency, resulting in reduced energy consumption and greenhouse gas emissions.

- Enhanced Plant Profitability: Optimal cleaning schedules lead to increased production throughput, reduced energy costs, and enhanced plant profitability.

- Reduced Maintenance Costs: By adopting a condition-based cleaning approach, unnecessary cleaning and associated maintenance costs are minimized.

- Enhanced Equipment Reliability: Regular cleaning at the right intervals helps maintain the integrity and reliability of heat exchangers, extending their operational life.

- Data-Driven Decision Making: The use of machine learning and optimization algorithms ensures data-driven decisions, maximizing the benefits of heat exchanger cleaning.

- Environmental Sustainability: Reduced energy consumption and CO2 emissions contribute to the overall environmental sustainability of the refining and chemical industries.

- Improved Asset Management: By better understanding fouling patterns and performance trends, plant operators can implement more efficient asset management strategies.

By implementing a data-driven approach for heat exchanger fouling prediction and cleaning schedule optimization, the refining and chemical industries can significantly improve heat exchanger performance, reduce energy consumption and emissions, enhance plant profitability, and optimize maintenance costs.