Real-Time Calculation of Asset Health based on Corroded Area Percentage

Problem

Asset management in industries like manufacturing, oil and gas, and infrastructure often involves monitoring and inspecting assets for signs of corrosion, which can lead to significant safety risks and operational inefficiencies if left unaddressed. Traditional manual inspection methods are time-consuming, costly, and may not provide real-time insights into the health of assets. Identifying areas with high corrosion rates is crucial to prioritize maintenance activities and prevent potential failures. The challenge is to develop a system that can accurately and efficiently calculate the health of assets in real-time based on the percentage of corroded area, reducing the need for manual inspections and enabling prioritized maintenance planning.

Approach

The approach to implementing real-time asset health calculation based on the percentage of corroded area involves leveraging IoT sensors, computer vision, and data analytics. Here’s a breakdown of the key steps:

- IoT Sensor Deployment: Install IoT sensors on assets, both internally and externally, to collect data on corrosion levels. These sensors can measure environmental factors like temperature, humidity, and corrosive gases, as well as asset-specific parameters like wall thickness or coating condition.

- Data Acquisition and Preprocessing: The IoT sensors continuously gather data on corrosion-related parameters. This data is preprocessed to remove noise, handle missing values, and ensure its accuracy and consistency.

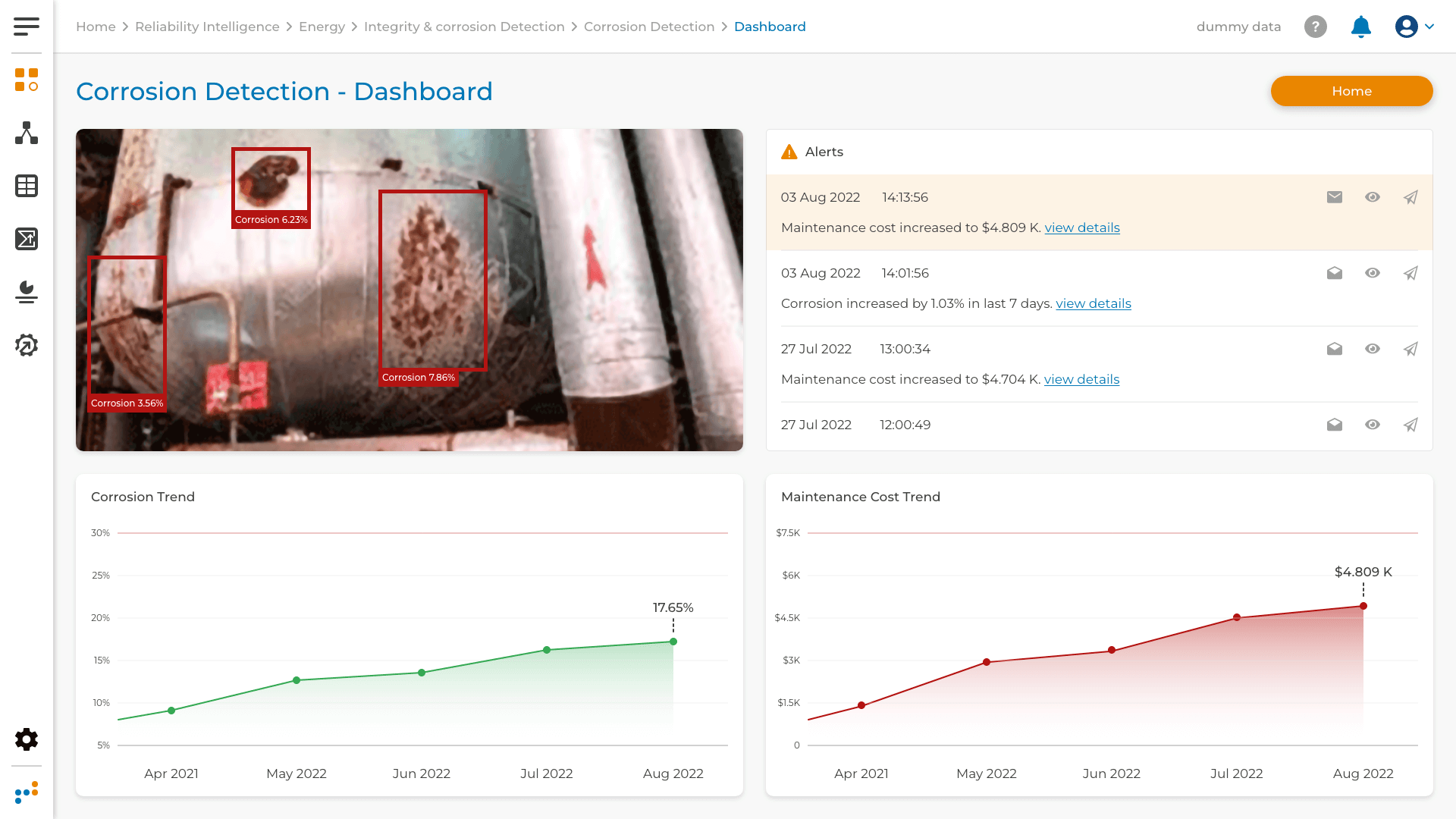

- Computer Vision for Corrosion Detection: For assets with visual surfaces, deploy computer vision algorithms to analyze images and detect areas of corrosion. These algorithms can segment corroded regions and calculate the percentage of the corroded area on the asset surface.

- Data Integration: Combine data from IoT sensors and computer vision outputs to create a comprehensive view of asset health. The integrated data should include the percentage of corroded area, environmental conditions, and other relevant factors.

- Health Index Calculation: Develop a health index or score based on the percentage of corroded area and other relevant parameters. The health index should represent the asset’s overall condition and potential risk of failure.

- Real-Time Data Processing: Utilize data analytics and machine learning algorithms to process the integrated data in real-time. This ensures that the health index is continuously updated as new data is collected, providing real-time insights into asset health.

- Prioritization of Maintenance Activities: Based on the health index, prioritize maintenance activities and intervention strategies. Assets with higher corrosion levels or deteriorating health would receive higher priority for maintenance, allowing for proactive planning and resource allocation.

- Alerts and Notifications: Implement an alerting system that notifies maintenance teams when an asset’s health index reaches a critical threshold or requires immediate attention. This enables timely responses and reduces the risk of unexpected failures.

Benefit

- Reduced Manual Inspection: By automating the corrosion detection process using computer vision and IoT sensors, manual inspection requirements can be reduced by up to 90%, saving time and labor costs.

- Real-Time Asset Health Monitoring: The system provides real-time updates on asset health, allowing proactive maintenance planning and minimizing the risk of unplanned downtime or failures.

- Cost Savings: Prioritizing maintenance activities based on asset health helps allocate resources more efficiently, reducing unnecessary maintenance costs and optimizing asset performance.

- Enhanced Safety and Reliability: Timely identification of corroded areas allows for prompt maintenance and repair, enhancing safety and prolonging asset life.

- Improved Asset Management: Accurate and continuous monitoring of asset health enables better asset management decisions, leading to increased operational efficiency and reduced operational risks.

- Increased Sustainability: Proactive maintenance and optimized resource allocation contribute to a more sustainable approach to asset management by reducing waste and unnecessary interventions.

- Compliance and Regulatory Requirements: Efficient asset health monitoring aids in meeting regulatory requirements related to asset inspection and maintenance.

By implementing a real-time calculation of asset health based on the percentage of corroded area, organizations can streamline maintenance operations, enhance asset reliability, and reduce inspection costs, leading to improved overall asset management and operational performance.